South Carolina CDL Pretrip Test

Boost your confidence: the essential cdl pretrip practice test prep, south carolina cdl pretrip inspection test: mastering the essentials.

Are you gearing up for the South Carolina CDL pretrip inspection test? Whether you're a seasoned CDL driver or just starting your journey in the commercial driving industry, acing the pretrip inspection is crucial. In this guide, we'll delve into the nitty-gritty of the South Carolina CDL pretrip inspection test, providing you with valuable insights and tips to ensure you're well-prepared to tackle this assessment with confidence.

Understanding the South Carolina CDL Pretrip Inspection Test

Before hitting the road, commercial drivers are required to demonstrate their knowledge and proficiency in conducting a comprehensive pretrip inspection of their vehicle. The South Carolina CDL pretrip inspection test evaluates your ability to identify and assess various components of the vehicle, ensuring that it's in optimal condition for safe operation.

Navigating the Examination Guidelines

Mastering the South Carolina CDL pretrip inspection test involves familiarizing yourself with the specific examination guidelines set forth by the state's Department of Motor Vehicles. From inspecting the engine compartment to examining the coupling systems and assessing the condition of essential vehicle components, each step of the inspection holds significance in ensuring the overall safety and functionality of the commercial vehicle.

Embracing the Importance of Thoroughness

When preparing for the South Carolina CDL pretrip inspection test, attention to detail is paramount. Every aspect of the vehicle, from the tires and brakes to the lighting and emergency equipment, demands meticulous scrutiny. By cultivating a keen eye for detail and a systematic approach to the inspection process, you can enhance your readiness for the test and, more importantly, contribute to the safe operation of commercial vehicles on the road.

Honing Your Inspection Skills

Beyond memorizing the checklist of inspection points, honing your practical skills through hands-on practice and real-world application is instrumental in excelling in the South Carolina CDL pretrip inspection test. Familiarize yourself with the nuances of different vehicle types and configurations, and immerse yourself in simulated inspection scenarios to simulate the test environment and build confidence in your abilities.

Tips for Success: Navigating the South Carolina CDL Pretrip Inspection Test

Commit to continuous learning.

As the commercial driving landscape continues to evolve, staying abreast of industry updates, regulatory changes, and technological advancements in vehicle design and operation is indispensable. By cultivating a mindset of continuous learning and professional development, you can fortify your knowledge and adaptability, empowering yourself to confidently tackle the South Carolina CDL pretrip inspection test and navigate the dynamic demands of commercial driving.

Seek Mentorship and Guidance

Harness the power of mentorship and seek guidance from experienced CDL drivers who have successfully navigated the South Carolina CDL pretrip inspection test. By gleaning insights from their wealth of experience and expertise, you can gain invaluable perspectives, practical tips, and best practices that can elevate your preparation and performance in the test.

In conclusion, mastering the South Carolina CDL pretrip inspection test encompasses a multifaceted approach that amalgamates theoretical knowledge, practical skills, and a commitment to ongoing growth and improvement. By immersing yourself in the intricacies of pretrip inspections and embracing a mindset of continual learning, you can position yourself for success in this pivotal assessment, setting the stage for a fulfilling and impactful career in commercial driving. So, gear up, embrace the journey, and ace the South Carolina CDL pretrip inspection test with unwavering confidence and competence.

- Register / Login

- Trucker's Forum

- Paid CDL Training

- Truck Driving Jobs

- CDL Practice Tests

- High Road Training

Pre-Trip Inspection Study Guide

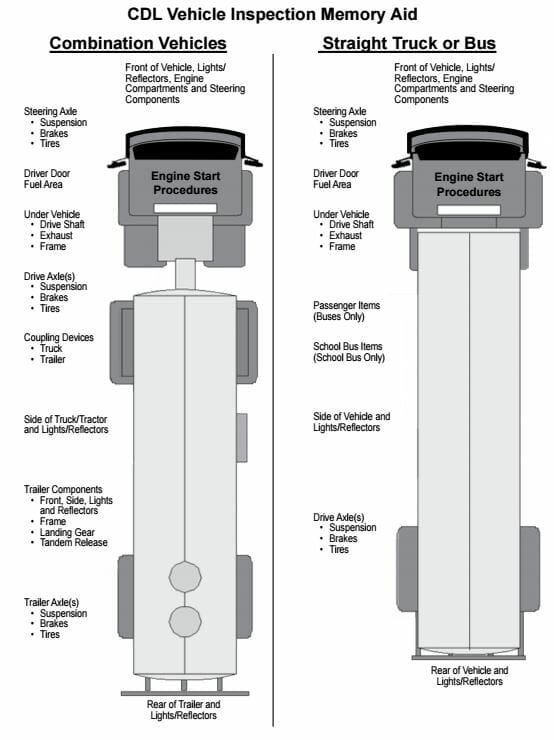

Our Pre-Trip Inspection Study Guide has everything you need to prepare for the Class A CDL Pre-Trip Inspection Exam . Our study guide will cover the pre-trip inspection terminology as well as a thorough list of all of the parts you will be inspecting on the vehicle. For each part you will be inspecting there will also be a list of items you will be checking for. Our study guide is broken down into the following sections:

- What You Need to Know About Pre-Trip Inspection

Pre-Trip Inspection Practice Questions

- Pre-Trip Inspection Checklist

Pre-Trip Inspection Videos

Pre-trip inspection printable resources, what you need to know about the pre-trip inspection.

The Pre-Trip Inspection is a thorough inspection of the vehicle and all of its major systems. Inspecting the vehicle before driving each day is a Federal requirement and normally takes about 15 minutes. It must be logged in your logbook as "on duty not driving."

You will have to do thorough safety inspections of the coupling system, the vehicle lights, engine compartment, tires and brakes, the chassis, the fuel tanks, and an in-cab inspection.

The following information is a brief summary of Daniel's Complete Pre-Trip Inspection taken from our oustanding free PDF download:

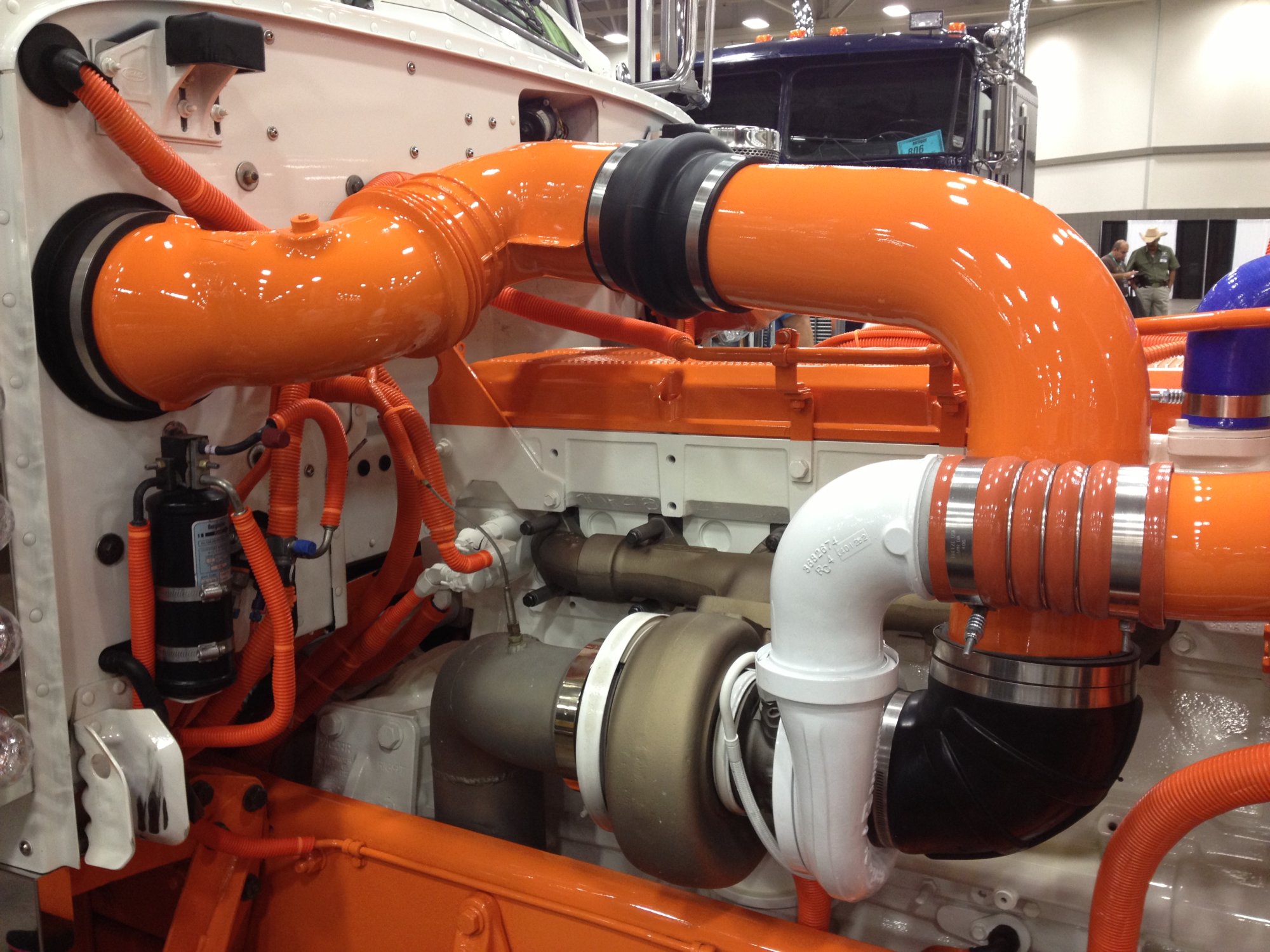

Engine Compartment

You will be checking the engine compartment for any sort of leaks. You will also be checking to see if all components are properly mounted and secured. None of the mounts must be cracked, bent, or broken.

You will be checking all hoses to make sure they aren't leaking, frayed, or sliced and the fluid levels including the oil level, the coolant, and the power steering fluid.

You must check the components like the water pump, the power steering pump, and the alternator to make sure nothing is leaking, the belts are not frayed, and that everything is properly mounted and secured.

From inside the engine compartment you will also find the steering system, the front suspension system, and the front brake system. All components of these systems must be properly mounted and secured without anything being cracked, bent, or broken. Finally you will be checking the tires, rims, and axle seals to make sure the tires are properly inflated, the rim isn't bent or cracked, and the axle seals are not leaking.

Fuel Tank And Battery Area

You will be standing along the side of the tractor doing a series of checks on the mirrors, fuel tanks, batteries, exhaust system, and more. You will check to make sure nothing is bent, cracked, broken, or leaking.

Check the mirrors, door hinges, door handle to make sure nothing is cracked, bent, or broken. Check to make sure there is no fuel leaking and that the fuel cap is secured and the gasket is not missing.

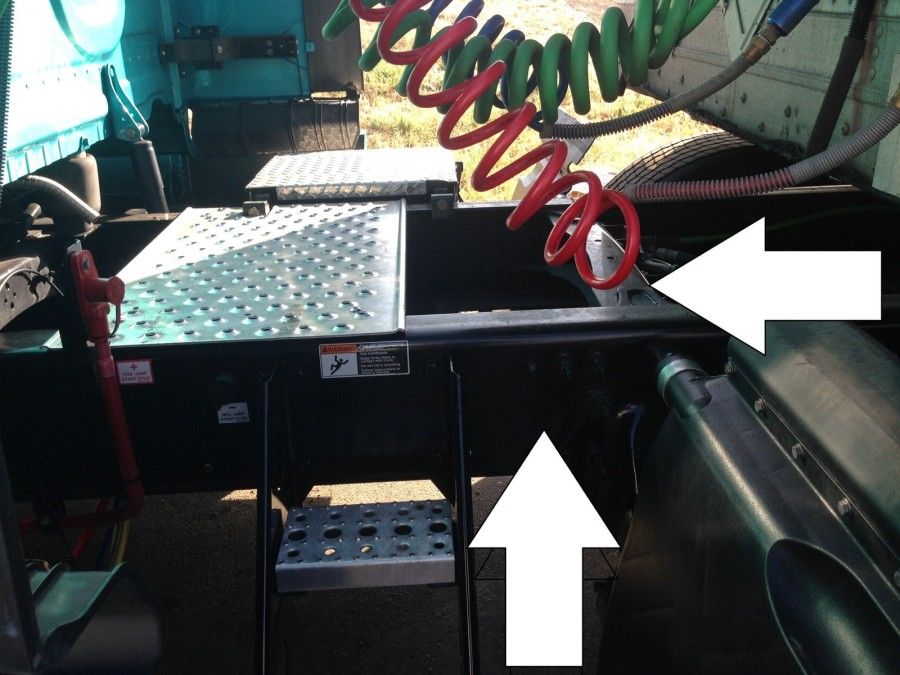

Check the exhaust system to make sure nothing is cracked, bent, or broken. Check the driveshaft, cat walk, and steps to make sure nothing is cracked, bent, or broken.

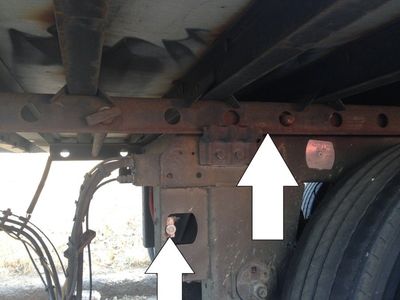

Check the frame and crossmembers for structural integrity. Check the air lines going to the trailer to make sure they're properly connected and that there are no abrasions, bulges, or cuts. Make sure the gaskets are present.

Check the suspension system and brakes on the drive axles, making sure nothing is cracked, bent, or broken. Make sure the brake linings are the proper thickness and that the air bags and properly inflated. Inspect the brake chambers, slack adjusters, and pushrods are properly mounted and secure. Not Cracked, Bent, or Broken. With the brakes released and pulled by hand, the Push Rod should not move more than 1 inch.

Check the rims, tires, and axle seals of the drive tires for proper inflation, no leaks around the seal, and the lugs are all present and secured.

Coupling System

You will be standing where the tractor and trailer are connected and you'll start by checking the electrical line and air lines to make sure they're properly mounted and secure at both ends. No abrasions, bulges or cuts. Not leaking air. Make sure the electrical line has no wires exposed. Check the gladhands to make sure the seals are in good condition, no cracks or signs of dry rotting. Not leaking air.

Check the skid plate of the fifth wheel and the apron of the trailer to make sure there is no debris and nothing is cracked, bent, or broken. Make sure the fifth wheel is properly greased. Also make sure there is no gap in between the fifth wheel and the trailer apron once the tractor and trailer are coupled. Make sure the kingpin of the trailer is properly mounted and not cracked, bent, or broken and that the locking jaws of the fifth wheel are properly secured when the tractor and trailer are coupled.

Check the mounting bolts where the fifth wheel attaches to the tractor frame. Make sure there are no missing bolts and that everything is secured properly. Check the locking pin if you having a sliding fifth wheel to make sure it's properly locked into place.

Make sure that there is the proper clearance space between the tractor mudflap and the trailer landing gear so that they don’t hit each other when making a turn.

You will start inspecting the trailer at the head board, which is the front wall of the trailer. Make sure there are no holes or missing rivets. Check the landing gear to make sure it is properly mounted and secure. Not cracked, bent, or broken. Make sure the fully raised and the handle is secure in the cradle when the tractor and trailer are coupled.

Check the frame and crossmembers under the trailer to make sure they're not cracked, bent, or broken. Check the tandem frame and release pins to make sure the frame is in good condition and the release handle and locking pins are in the fully locked position.

You will check the entire suspension and brake system for the trailer tandems the same way you did for the drive axles of the tractor. You will also make sure the mudflaps are properly secured. For dual tires check to see that there is proper space between the tires and there is nothing stuck between the tires.

Check the rear door and hinges to make sure they are properly mounted and nothing is cracked, bent, or broken. Make sure the door seals are not worn, torn, or dry rotted.

Light Check

You will be checking all of the lights and reflectors on both the tractor and the trailer. Check the reflectors and reflective tape to make sure they are properly mounted and secure, not cracked, bent, or broken, and clean and illuminated. Check that you have the proper color of amber to the front and sides, and red to the rear.

Start by turning on your marker lights and headlights. Now walk around the entire truck and trailer and point out the lights. Give the function of the light and the location. You should then ask your examiner to help you check your five functions.

While you're sitting in the drivers seat, the examiner will stand to the front of the truck, then behind the trailer. He will then check your Turn Signals, Four Way Flashers and Brake Lights. You must do each function at every location.

The five locations that you must check your lights:

- Front of the Truck

- Both sides of the Truck

- Rear of the Truck

- Both sides of the Trailer

- Rear of the Trailer

The Five Functions you are checking for:

- Left Turn Signal

- Right Turn Signal

- Four Way Flashers

- High Beams/Low Beams

- Brake Lights

In-Cab Inspection

The in-cab inspection and air brake check will cover the various gauges and systems inside the cab along with several tests to make sure you air brake system is working properly.

You will start by checking the following:

- Seat Belt- Properly Mounted and Secure. Not ripped or frayed Adjusts and latches properly.

- Fire Extinguisher- Properly Mounted and Secure. Fully charged

- Three Red Reflective Triangles- My three red reflective triangles are GIVE LOCATION

- Spare Electrical Fuses- My spare electrical fuses are GIVE LOCATION

- Volmeter, Oil Pressure Gauge, Water Temperature Gauge, and Air Pressure Gauge all show proper operation

- City horn and air horn functioning properly

- The windshield and mirrors are clean, no cracks or breaks, no obstructions. The mirrors are in proper adjustment.

- Windshield Wipers and Washers - Demonstrate that the washers work by spraying the windshield. The Wipers are: Properly Mounted and Secure and operate smoothly. The blades aren't cracked or dry rotten.

- Heater and Defroster - Demonstrate that both the Heater and Defroster are working properly.

- Lighting Indicators - Left Turn, Right Turn, Four Way Flashers, and High Beams.

Trailer Parking Brakes - Set the Trailer Brake, release the tractor brake, and then tug lightly on the trailer.

Tractor Parking Brakes- Then set the Tractor Brake, release the trailer brake, and then tug lightly on the tractor.

Service Brake Check - Release both Tractor and Trailer Brakes. Now drive at idle speed. Apply the Service Brake to make sure you come to a complete stop, and that it doesn't pull to the left or right when applying the brakes.

Air Brake Test

The air brake test will consist of a leakdown test to make sure your air brakes aren't leaking air and losing pressure. It will also test the warning lights and buzzer to make sure the driver gets the proper warning if the air pressure drops too low.

There are three stages to an Air Brake Test

#1: Applied Pressure Test

#2: Warning Light and Buzzer

#3 Tractor/Trailer Protection Valve Pop Out

Applied Pressure Test: Build the air pressure to governor cut out. Put the truck in the lowest gear. Then turn off the engine Immediately turn the engine back on. Push in both the tractor and trailer valves. (This will release the parking brakes.) Push and hold the Brake pedal fully. Allow the gauges to stabilize. Announce the gauges have stabilized and the Primary and Secondary PSI. With the Brakes fully pressed, you should not lose more than 4 PSI in one minute. Announce that you are listening for air leaks during that minute.

Warning Light and Buzzer Test: Pump down on the Brake pedal until the warning light and buzzer comes on, at or before 60 PSI.

Tractor/Trailer Protection Valve Pop Out Test: Pump down on the brake pedal until both the tractor and trailer protection valves pop out. They should both pop out between 40 and 20 PSI.

We have a ton of Pre-Trip Inspection Practice Questions along with the answers and a complete scoring system in our Free Online CDL Practice Tests :

The Engine Compartment Section will include questions about checking the oil level and coolant levels, inspecting belt-driven engine components (like the water pump, alternator, and air compressor), and the safety devices required in the cab. There will also be questions regarding the windshield wipers and free play in the steering wheel.

The Lights And Brakes Section will include questions about dashboard indicator lights, inspecting the parking brakes, and doing a leakdown test on the air brakes. It will also include questions about the low air pressure warning signal and testing your air horn and city horn.

The Suspension And Steering Section will include questions about the tractor protection valve, inspecting the steering box, and inspecting many suspension system parts. It will also include questions about welds being present on tire rims and the minimum tread depth required on steering axle tires.

The Tires And Coupling Devices Section will include questions about shiny trails or rusty threads on lug nuts, inspecting the battery box and cover, and inspecting electrical lines. It will also contain questions about inspecting the coupling devices and the fifth wheel skid plate.

The Emergency Equipment And Fifth Wheel Section will include questions about additional emergeny equipment required by school buses, inspecting the gap between the kingpin apron and the fifth wheel skid plate, and the landing gear securement. It will also contain questions about inspecting driver mirrors and the trailer frame.

Pre-Trip Inspection Checklist - Class A

Our pre-trip inspection checklist covers every part of the truck from front to back, both inside and outside of the truck. It covers the air brakes, suspension parts, steering components, wheels and rims, fuel tanks, batteries, lights, and more. It also covers the air brake tug test and checks for everything under the hood including alternator, water pump, fuel pump, fluids, and more.

This is a super handy checklist to study anytime you have a few minutes to spare:

Pre-Trip Inspection Checklist - Free Word Document Download (Editable Version)

Pre-Trip Inspection Checklist - Free PDF Download (Print Version)

Pre-Trip Inspection Video By Apex CDL Institute

Jeff from Apex Institute does an in-depth explanation of the entire pre-trip inspection process. This video is loaded with tips that go beyond the CDL test to help drivers really understand how to identify problems.

Pretrip Inspection Self-Test By CDL College

The Pretrip Inspection Self-Test By CDL College is really unique. It's a silent video which will show you the part you're inspecting and then gives you a few seconds to figure out what you should be checking for before giving you the answer. Definitely check this one out. Great for practicing before the CDL exam.

Pre-Trip Inspection Video By Averitt Express

This is a complete back to front pre-trip inspection of a truck and trailer by Averitt mainentance associate Kevin Breeding. This thorough pre-trip inspection covers all inportant points of inside the cab, lights, engine, the tractor itself and the trailer.

We have included two print versions of the pre-trip inspection process from Daniel. The first is the entire pre-trip inspection and the second is an abbreviated checklist for the inspection.

- PDF: Daniel's Pre-trip Inspection (Print Version)

- PDF: Daniel's Pre-trip Inspection Checklist (Print Version)

Why Join Trucking Truth?

- The High Road Training Program

- The High Road Article Series

- The Friendliest Trucker's Forum Ever!

- Email Updates When New Articles Are Posted

Apply For Paid CDL Training Through TruckingTruth

Did you know you can fill out one quick form here on TruckingTruth and apply to several companies at once for paid CDL training? Seriously! The application only takes one minute. You will speak with recruiters today. There is no obligation whatsoever. Learn more and apply here:

- Privacy Policy

Best Free CDL Pre-Trip Inspection Checklist | Trucker Safety & Profit

Table of Contents

The indispensable CDL pre trip inspection checklist is one of the most important rituals of a driver's day. Industry veterans know this routine like the back of their hands—it's that vital to the trade— but new drivers struggle with how to remember their CDL pre trip inspections, especially for the exam.

Drivers are required to complete this walkthrough at least every 24 hours, after their mandatory 10-hour break. A detailed inspection can safeguard not only your safety but also that of everyone else on the road.

This article will walk you through an exhaustive checklist to follow before every trip, as well as the potential costs of not doing so. We've designed this list with YOU in mind, so we're throwing in some money-making tips that will help you avoid steep fines and costly repairs.

"Spotting and fixing vehicle defects early on keeps you safe and your truck in good shape."

Why Following the CDL Pre-Inspection Checklist is So Important

The price of a failed DOT inspection makes completing a thorough CDL pre trip inspection checklist even more pressing. Violations can cost carriers thousands each year in both penalties and out-of-service (OOS) trucks. According to the FMCSA, around 20% of vehicles are OOS due to failed inspections at any given time. For an owner-operator, this means you'd be paying thousands in vehicle payments on a truck that's not earning you any money.

The pre trip checklist is designed to avoid any possible accidents due to equipment failure and failed safety inspections. A few minutes of caution pays for itself ten-fold down the line.

DOT & Truck Inspection

- Steer Axle/ Rear Suspension

- Side of Cab

- Rear of Cab

Driver Shaft/Rear Frame

- Trailer Front/Side/Rear- Trailer Suspension

Gauges/Inner Truck

- DVIR form fill out

"Most pre-trip truck inspection lists cover safety. We go beyond that with time and money-saving tips in our pre-trip inspection checklist PDF." - Brian Smith, Director, Global Marketing of Cota Systems

- Get the Google Sheet

- Download the Printable PDF

General Tips Throughout Your Pre-Trip Inspection

Because you don't have access to a pre trip inspection checklist during the CDL exam, drivers have created a few tricks to pass this part of the test. The most common memorization tricks are:

BBC: Is any plastic or metal bent, broken, or cracked?

CDL: No hard materials should be cracked, damaged or loose.

ABC: Are there any abrasions, bulges, or cuts on the rubber?

PFL: Peak for leaks in fluid and air containers.

PMS: Are bolts properly mounted and secure?

ABCDF: Do you see abrasions, bulges, cuts, dry rot, or frays?

A bit of common sense will help you put these acronyms to good use. For example, there's no way BBC would apply to rubber, as rubber wouldn't be bent, cracked, or broken. Most drivers pick one for each material type and stick with it until they get more comfortable with the list.

What are the ABCS in a pre-trip inspection?

As mentioned above, the ABCs refer to Abrasions, Bulges, and Cuts to check for during the Class A CDL pre-trip inspection. This applies to rubber or soft surfaces - things like tires, hoses, and rubber bushings.

How Long Should a Proper CDL Checklist & Inspection Take?

Ideally, it takes 15-30 minutes to run through the CDL pre trip inspection checklist depending on experience level and whether or not any issues are found. If issues are found, they must be fixed right then, before taking any more loads.

The cost of preventative maintenance averages $15,000 per truck per year. This figure is a drop in the bucket compared to the cost of inoperable equipment. Breakdowns and crashes due to mechanical failure cost carriers billions industry-wide. Consider an owner-op paying $3,500 per month on insurance and loan payments. Those payments still have to be made regardless of whether the truck is in the shop or on the road. Adds up quickly right? Spending a bit of extra time and money on prevention keeps trucks on the road and earning money.

Get your Free CDL Pre-Trip Inspection checklist today!

Standard cdl pre trip inspection checklist.

Our pre-trip inspection Class A checklist serves two purposes: helping new drivers pass this portion of the CDL exam, and guiding CDL holders through the process with 100% accuracy every time.

A few exam tips before the pre-trip checklist:

- Point to or physically touch each area being inspected. This will help your memory and prove you know your stuff.

- Start with a big section and break it down into small sections from left to right like reading a book.

- During the test, make at least 2 checks for every item or area.

▢ Hoses: all hoses should be secured on both ends with no splits or cuts

▢ Fluids: engine oil, washer fluid, coolants, and power steering

▢ Belts: no more than 1/2"" to 3/4"" of give, securely mounted with no fraying ends

▢ Alternator: securely mounted, belt in good shape

▢ Water pump: properly mounted with no split or leaking hoses

▢ Air compressor: securely mounted, no visible or audible leaks

If Left Unchecked:

Oil leaks and coolant issues are two of the most common breakdown causes, both of which can be spotted during pre-trip. Scheduling dry maintenance every 10,000-25,000 miles and wet maintenance every 25,000-50,000 miles can prevent most engine issues. These regular services, ranging from $50-$450 , are nothing compared to the price of replacing or rebuilding an engine - $20,000 - $40,000 . Thorough pre-trip inspections are the best way to avoid engine breakdowns and escalated damage.

▢ Brake Pads: ¼ minimum brake pad thickness

▢ Slack Adjuster: 1” of play and at a 90' angle to the brake chamber

▢ Brake Chamber : no audible leaks or visible damage

▢ Brake Hose: securely mounted, no audible leaks, splits, or cuts

▢ Brake Drum: no bluing from excessive heat, securely mounted

Brake problems are the most common cause of semi-truck accidents . While over-breaking is a big player in this, a lack of maintenance and unnoticed airline damage usually play roles, too.

Brake pad replacement costs $150-$300 per axle ($750-$1,500 total) and $80-$160 per hour in labor. The consequences of brake failure are incalculable - body repairs, cargo damage, and strikes to your carrier safety rating will follow you. The last thing you want to deal with is higher insurance premiums or trouble getting placed on loads. Take this part of your pre-trip inspection extra seriously.

- Front: clearance lights, headlights, high beams, turn signals, flashers

- Sides: turn signals, flashers, clearance lights

- Rear: tail lights, brake lights, left turn, right turn, 4-way flashers

- Front: clearance lights

- Rear: clearance lights, tail lights, license plate lights, brake lights, turn signals, flashers

▢ Reflector Tape: clear, free of dirt

If Left Unchecked:

Fines for a headlight out vary from state to state, but the consequences of non-functioning brake lights or turn signals could confuse drivers and create unsafe situations. Both of these can be spotted and fixed during a pre-trip inspection. It's easy to run to the shop and change the light yourself if possible. License plate bulbs are just a few cents, and headlight kits range from $40-$250 . Don't add the price of a ticket on top from getting pulled over!

On the topic of lights, it's important to note that warning lights like the engine light or battery alert light should be addressed immediately to avoid developing into bigger issues down the road.

▢ Wheel inside: not broken, no illegal welds

▢ Wheel outside: no cracks or illegal welds

▢ Tires: no cuts or bulges, air gauge matches manufacturer recommendations, tread depth at least 4/32" and evenly worn

▢ Spacing: duals are properly spaced

▢ Valve Stem: not audibly leaking. metal cap in place and secure

▢ Lug Nuts: present, tight, no cracks

▢ Hub Seal: not cracked or loose

Tire problems cause 8,000 truck accidents per year. While flats are sometimes unpreventable, blowouts can be caused by improper inflation , which can also shorten the lifespan of your tires via irregular wear and tear. Timely alignments and rotations can also keep tires running longer; the price of new big rig tires is from $250 to $600 . A tire blowout mid-load can make you miss your appointment and waste precious driving hours - all the more reason to be thorough in your truck inspection.

Something to keep in mind is the way you conduct your pre-trip checklist is important. For example, there are a lot of videos and content showing truckers how to check their tires by kicking, beating, and even using a hammer. Hitting a tire with force like that, in the right spot (damaged) can lead to a blow-up and severely injure you and your truck. Even lugging around a damaged tire can lead to a blow-up . Stay safe and take all necessary precautions!

Steer Axle/Rear Suspension

▢ Steering Shaft: not BBC, securely mounted

▢ Steering Gear Box: not BBC, securely mounted, no visible leaks

▢ Hose: no visible leaks, properly mounted

▢ Pitman Arm: not BBC, securely mounted, nuts and pins are all hardware is present and secure

▢ Drag Link: rubber is in good shape, bushings are properly greased and not split or cut

▢ Upper/Lower Control Arms and Tie Rod: not BBC, securely mounted

▢ Spring Mounts: not BBC, securely mounted

▢ Leaf Springs: not BBC, securely mounted, not shifted or scissored

▢ U-bolts: not BBC, securely mounted, all accounted for

▢ Shock Absorber: not BBC, securely mounted, no visible leaks, rubber bushings aren't dry rotting

If Left Unchecked:

On their own, each of these parts isn't a huge deal to replace. For example,

- Steering Shafts: $100-$300

- Pitman Arms: $50-$200

- Steering Gear Box: $150-750

- Shock Absorber: $50 - $90

On the other end of the spectrum, neglect can lead to the truck leaning to one side, which can cause further damage. Blown shock absorbers will also make your truck hard to handle, steer, and control. Say it takes a mechanic 3-5 days to diagnose and fix a suspension issue. You could lose out on $1,000 - $3,000 in earnings that week, plus the several hundred it will cost in repairs. Spotting these issues during your 15-minute pre-trip inspection could save you thousands.

▢ Mirrors: mirrors adjusted properly and without cracks, free of dirt

▢ Foot Pedals: unobstructed

▢ Horns: functioning properly

▢ Windshield: no stickers, cracks, or excessive dirt

▢ Heater/defrost: both operate when the fan is set to max

▢ Wipers: arms move properly when turned on, and wiper fluid works

▢ Steps: mounted and secured

▢ DEF cap: secured

▢ Fuel cap: gasket and vent in place, chain secures cap to the tank

▢ Skirting: no damage, panels secure

To be mid-trip and discover your defrost or wipers don't work can be a scary feeling. A suddenly obstructed view with no way to clear it is what the in cab inspection is meant to avoid.

With the average truck eating up $15,000 per year in maintenance and repairs, it's the little things that add up to such a steep number. For example, fixing a windshield can cost anywhere from $500 - $2,000, depending on the truck type and severity of damage. Wiper blades cost $14 - $35 on average, and an AC compressor would cost around $200 to fix/replace . It's easy to see how these numbers add up fast, but waiting until something breaks on the road and taking on the cost of an OOS violation can quickly double and even triple those numbers.

▢ Frame: no illegal welds, not BBC, no rust

▢ Drive Shaft: not BBC, properly mounted, not twisted, and the U-joints are clean

▢ Universal joint: not BBC

▢ Differential: no leaks

Rusting frames and chassis can be prevented and stopped in their tracks with preventative protective sprays . To protect a drive shaft, keep it free of dirt and debris and make sure it's well lubricated. The price of a new driveshaft is around $1,200 . The cost of checking it during pre-trip is free. Remember, the purpose of a pre trip inspection Class A is to not only keep you safe but to spot mechanical issues before they get worse.

▢ Bolts/Bracket: all accounted for and secure, not broken or bent

▢ Locking pins: all accounted for and secure, not broken or bent

▢ Release Handle: releases freely and is in the locked position.

▢ Apron: no cracks, no gap between apron and 5th wheel plate, securely fastened

▢ Skid Plate: no cracks, properly greased, securely mounted

▢ Platform: securely mounted, not cracked or broken, no illegal welds

▢ Kingpin/Locking Jaws: locking jaws are wrapped around kingpin, which is straight with no chips or welds

▢ Air Lines: securely mounted at both ends. Lines are free of cuts, no audible leaks.

▢ Electrical line: secured at both ends. Lines are free of cuts, no audible leaks.

The consequence of worn brackets or pins is accidental uncoupling, otherwise known as dropping a trailer. Not only can this cause accidents, but it can damage the trailer and the cargo inside. In these cases, the carrier is almost always liable for any damages.

▢ Header Board: properly mounted and secured, not BBC, no missing rivets

▢ Clearance lights: not loose, cracked, or dirty

▢ Top rail: No cracks or collision damage.

▢ Rivets, holes: no holes, all rivets in place.

▢ Landing gear: properly mounted and secured, not BBC, shoes are present, handle moves freely

▢ DOT tape: covers at least 50%, not dirty or peeling

▢ Floor: no holes

▢ Cross members: none are damaged, missing, or twisting

▢ Tandem release: properly mounted and secured, not BBC

▢ Slide rail: properly mounted and secured, not BBC

▢ Pins: engaged

▢ Clearance lights: not cracked or dirty

▢ Doors: not broken, no holes, seal intact

▢ Hinges: securely mounted, not BBC

▢ Door handles and rods: securely mounted, functioning properly

▢ Lights: securely mounted, not cracked or dirty

▢ DOT tape: clean, covers 100% of the backside of the trailer

▢ Bumper: properly secured, not BBC

The trailer keeps your precious cargo safe. Issues with the cross members, flooring, or doors leave cargo unsecured and exposed to the elements. Of this list, the most expensive fix is replacing or repairing cross members. Just one broken cross member puts a truck OOS, and repair/replacement costs thousands , mostly in labor. How can they get damaged?

- sloppy hooking/unhooking

- exposure to the elements

- uneven loading

- punctures from inside the trailer

- blown tires

If you notice trailer damage during your Class A pre-trip inspection, you'll have to get it fixed before taking any more loads.

▢ Air pressure: set to proper operating range, no warning lights

▢ Temperature gauge: rising to proper operating range, no warnings

▢ Oil pressure: rising to proper operating range (25-50 PSI), no warnings

▢ Voltmeter: operational, 13 - 14 volts

▢ Dashboard light indicators: check the indicators for the high beams, turn signals, and flashers.

▢ Fuel: gauge matches visual compared to looking in the tank

▢ Tachometer: 1000-1500

▢ Water temperature: 180-205 degrees

▢ Def level: minimum of one light bar

If these gauges don't pass the pre trip inspection Class A checklist, it's likely due to faulty wiring or a fuse issue. You'll have to identify the source or take it to someone who can.

Simple electrical fixes can be done on your own. At a mechanic, a blown fuse costs around $100 to repair, and a full rewiring can cost anywhere from $1,000 - $2,000 .

Preventative maintenance includes replacing old connections with more modern technology and having circuit protectors checked during regular maintenance.

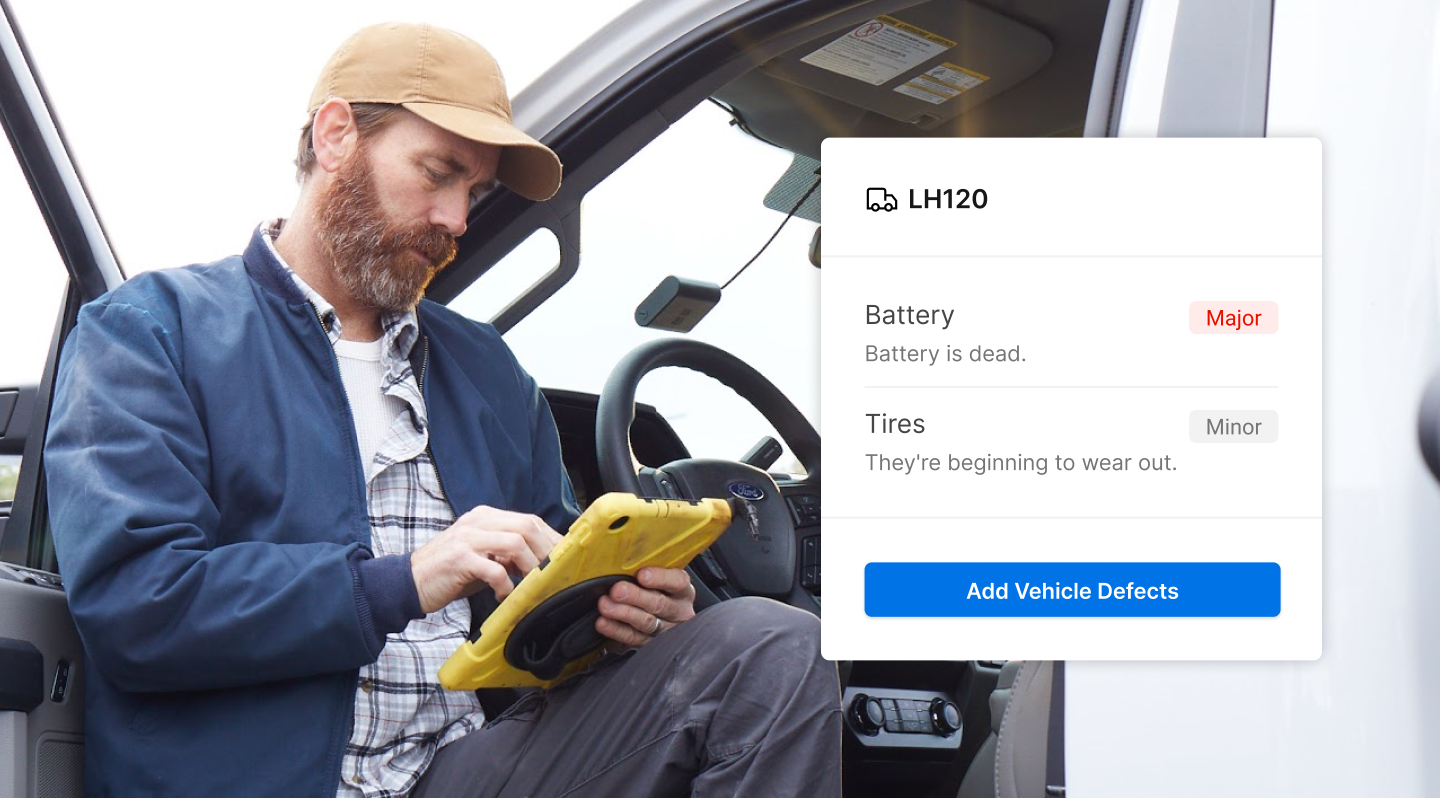

A DVIR, or Driver's Daily Vehicle Inspection Report, is the form that drivers fill out during the Class A pre-trip inspection and at the end of their day. It's designed to keep the company informed of any missing or damaged parts of the truck, keep maintenance costs as low as possible, and keep trucks on the road safely.

Drivers should keep their completed forms accessible and stored for up to 6 months, just in case they're asked to pull them for reference.

Most Common Issues Found During Pre Trip Inspection

Below are the most common issues found while running through a CDL pre trip inspection checklist. If left unchecked, these things can lead to getting pulled over and receiving a violation, or worse, causing a breakdown where you or others are hurt.

Here's a run-through of what to do if you run into these common issues and how to avoid them."

Broken Lights

What to Do:

The first of the three L's (lights, leaks, and leans), broken lights are an easy way to get pulled over and trigger a full-blown roadside inspection. If you notice an issue with one of the many lights during your truck inspection, you're required (and it's in your best interest) to get a replacement immediately.

How to Avoid This:

Obviously, there's no way to avoid lights going out. However, you can avoid faulty reflectors by getting regular washes, especially if you've driven somewhere rural or salted. Shippers appreciate a clean truck, too.

Maintenance as a Money Saver:

Lighting violations are known as ""gateway violations"" because they open the door to law enforcement noticing other things wrong with the truck. This makes staying on top of maintenance even more pressing. For example, most new reflectors cost around $5 each . If you get pulled over for missing or faulty reflectors, it could trigger an inspection that makes you A) sit still and waste hours, B) miss your appointments, C) end up OOS, and D) get in trouble with your company.

Leaning is the second of the three L's. A leaning truck could indicate

- tire problems

- faulty suspension

- worn spring bushings

- airbag issues

The first step is to check out the above mechanisms yourself for any noticeable worn springs or airbag problems. To avoid damaging any equipment even further, go to the shop after your pre-trip inspection and get it checked out.

Uneven loading puts excess strain on the truck and can cause leaning over time. You have every right to ask shippers to fix uneven or shoddy loading.

A new leaf spring is one common solution to fixing a leaning truck. Costing anywhere from $80 - $450 , it's a solid first step compared to full suspension repair which costs $1,000 - $2,000.

The last of the three L's are leaks. When you look on the ground near the engine, do you see any puddles or fluids? There are three common sources:

- power steering

- water leaks

- brake fluid

Identify the source. What type of liquid is it? Does it smell? How big is the puddle? Is the radiator cap secured and not broken? If you can identify the problem and fix it - great. If not, make a call to the nearest shop.

The reason you check every bolt and hose on the pre trip inspection Class A checklist is to avoid these mystery leaks. Preventative maintenance is key.

Maintenance as a Money Saver:

It's a lot cheaper to replace nuts and bolts than it is to replace an entire system that's been damaged due to ongoing leaking. Driving with a leaking radiator can damage engine bay components and require repairs to a chain of other parts. If the problem was the radiator gasket, for example, the cost of a replacement would only be around $40 .

The limit for tread depth is 4/32" on steer tires and 2/32" on others to pass a Class A pre trip inspection. Sometimes tires look good during inspection, but after a long haul, treads have worn down too low.

Tire replacement should be prompt - blowouts happen all the time and can do serious damage to the underside of the trailer. Check if the tire is still under warranty, and have it and any others replaced ASAP.

Make sure tires are always filled to the manufacturer's recommendation and ideally the same PSI in each tire. Note that tread loss accelerates in extreme heat. Tires gain about 1 pound of pressure every 10 degrees as the temperature increases. Asphalt can be 20-50 degrees hotter than the air; keep that in mind before thinking any bulges or worn tread will be fine.

New big rig tires cost $250 - $600 , or $0.04 per mile. Because of the high cost, many large fleets are opting for imported tires to keep costs down. Research reviews on the brand you have in mind first - many have bad reviews from truckers. Here's a video that shows how much time can be lost by blowing a steer tire.

Overheating

Pull over safely and legally. Give the truck some time to cool down in idle. Try turning the heat on to get some of that heat out of the engine - it will feel uncomfortable but protecting the engine is worth it. Check to see if the radiator is jammed with debris or has bent fins. An overheating truck could be difficult to diagnose, and you'll most likely have to have a mobile mechanic come to you. If you were going up a steep grade, it might have just been the way you were driving.

- Keep the radiator clean

- Check the muffler for soot build-up in older trucks

- Don't use cruise control in hilly areas

- Don't overload the trailer

Constant overheating can be hard to diagnose, and it can make you chronically late to appointments. Regular maintenance and a thorough CDL pre trip inspection Class A are where the little details can be spotted and nipped in the bud.

Cota Systems Make More Money Per Mile CDL Pre-Trip Checklist

We know the struggle of hauling empty or partially full trucks and deadheading between every load. Our solution? Seamlessly connecting truckers with available LTL loads that complement their route and trailer capacity. Free and easy to use, Cota Systems™ platform makes it simple to earn more money per mile. We'll send you available LTL truck loads on your preferred routes as soon as they're posted.

Simply sync all of your favorite load boards into Cota Systems™ for easy browsing and instant notifications.

COTA SYSTEMS™ Mobile App

Cota Systems™ mobile app connects drivers with new loads and their dispatchers no matter where they are.

- Extra loads on the road.

- Scan and send documents.

- Keep track of your earnings.

- Seamless dispatch integration.

- Real-time load notifications.

- Stay connected anywhere.

Whether you're trying to figure out how to find box truck loads , or you just aim to connect in real-time, anytime, staying efficient on the road makes the difference between staying profitable and staying afloat.

Our trucking dispatch software is completely free and feature-rich, saving teams time on paperwork and document sharing. The platform integrates seamlessly with the driver app simplifying everything from load finding to billing.

How Cota Systems™ helps drivers 10X their income:

- Eliminates wasted miles with convenient LTL and partial load boards

- Efficient document uploading and one-click billing

- Communicate with shippers in the same app

- Load board syncing cuts down the time it takes to book a load

Bypass Construction

The DOT 511 traffic app provides state-specific traffic and construction updates. Check for delays on your route to get ahead of detours and lane closures. Each state has their own app, so download it ahead of time.

Why does it matter? If you earn $0.60 per mile on a 400-mile trip, that's $240 earned in roughly 8 hours. Now, say traffic adds 1.5 hours to your trip. You still earn the same $240 AND you don't have the opportunity to pick up another load before you reset. Time is money!"

In 2016, truckers were delayed a total of 1.2 billion hours because of congestion on the road - that's in the billions! Truck bottlenecks are mostly common in major cities. Planning your route ahead of time to avoid traffic delays is crucial to your bottom line.

Weather Apps

Winter and summer storms can eat into income and create seriously dangerous roads. Depending on the weather, you might be able to plan a different route to avoid delays or change the time and place you stop to rest. The AccuWeather app is a popular choice among drivers.

The horror stories of drivers getting stuck at a rest stop for days or getting blown over by strong winds paint the ugly picture of the weather as a driver's biggest opponent.

Truck Parking

After finishing your Class A CDL pre trip inspection, take a few minutes to map out overnight parking spots along your route. American Truck Parking does a good job of showing truck stops and rest areas that offer overnight parking, as well as the pricing, pictures, and other amenities. You can filter out for gated parking spots, CAT scales, showers, truck washes, and much more. Compare pricing beforehand and save yourself the cash!

Speaking of cash, it's important to take advantage of freight factoring. This method can offer truckers immediate cash flow, while waiting on customers to pay.

In addition to managing your cash flow, be sure to consider freight insurance , this protects your trucks and cargo from any potential risk during transit.

Dock Details

Headed to a new shed? Check them out on Dock 411 to confirm things like pallet restrictions and hours of operation. Not sure if you can fit? Most places have pictures that other drivers took or reviews about slow loading and yard hazards.

The benefit? This helps plan things like getting lunch, calculating hours, and knowing whether or not you even want to take a certain load. If you see reviews that a shed has an average 7-hour loading time (the standard is 2.5 hours ), you can have a conversation with dispatch early on to make a game plan regarding detention and/or layovers.

While researching docks, don't put your well-being on the back-burner. Be sure to invest in the right truck mattress for a good night's sleep during layovers or breaks.

Gas Buddy helps truckers find the cheapest gas prices along their route. While you're looking, you can see what stops have showers, food, repairmen, and other amenities so you can save time at a 1-stop shop.

For reference, the average owner-operator spends $45,605 on fuel per year ( 2022 ). Company drivers don't usually have this problem since they have discounted fuel cards. (You can get fuel cards with Cota Systems , too). To learn more, check out our post on the best fuel cards for truckers.

Legally Bypass Inspection Sites

Did we mention that time is money? Another way to save time is with Drivewyze , an in-cab app for driver devices that provides inspection bypass opportunities at 884 weigh stations across the states. When bypass isn't allowed, they have an e-inspection system that speeds up the process and avoids long lines. It sounds too good to be true, but it's 100% legal and works 89% of the time. Prepass is another company that offers this service.

Weigh station stops can take anywhere from 30 minutes to a few hours if lines are long or they find something wrong with your truck. That 30-minute stop could have earned you $15 (at $0.60/mile for 25 miles). Doing so every day could cost you $300/month, and that's IF the stops only take 30 minutes!

Most drivers use a combination of navigation apps. Hammer and Google Maps are popular choices. Systems made specifically for truckers won't take you down prohibited roads - that's why Google Maps alone might not cut it.

Health Apps

Recent studies found that workers who take care of their mental health average 9.3 fewer sick days per year than workers who don't. The life expectancy of truck drivers is 61 years , partly due to their unhealthy lifestyle and work-related stress. Your health is just as important as any CDL pre-trip list. Obesity is one of the most prevalent health issues in the trucking industry for long-haul drivers. These healthy habits can save you down the line:

- Skip the fast food, sugary snacks, and sodas.

- Find a way to manage your stress. Talking to a friend while you drive or finding a podcast that you enjoy are two common solutions.

- Exercise during home days focusing on your back.

- Switch up your stimulants. Instead of Redbull every day, try green tea, coffee, or Yerba Mate a few days per week.

Try out some apps like MyFitnessPal for weight loss and nutrient tracking or Luminosity for mental health support.

OTR drivers can take advantage of toll services like Prepass (which also serves as a weigh station bypass) and Best Pass , a prepaid transponder system. If a toll company isn't covered, it's best to just use cash and keep your receipt. A few tips:

- Take a second to review toll prices on your trip. Any tolls should be factored in when dispatch discusses rates, especially in cities.

- Find and join any toll discount program you can find (take the New York toll reimbursement program, for example)

- Best Pass offers cash toll discounts, but you should verify that the transponder rate wouldn't have been the same (and much faster).

How to Remember Pre Trip Inspection CDL Checklist

Start with our printable CDL pre trip inspection cheat sheet and repeat, repeat, repeat. Use the same checklist every time so your brain can get into that rhythm. Remember the acronyms:

BBC: Bent, broken, or cracked

ABC: Abrasions, bruises, cuts

PFL: Peak for leaks

3 L's: Lights, leaks, leans

Understanding the mechanics of the truck and how everything works together will help your brain form stronger connections and remember more. Try explaining the process to your wife, kids, or friends (even if they won't remember) so you can spot areas you need to study the CDL pre trip inspection PDF more.

What is the item most commonly overlooked during a pre trip inspection?

A few items on the CDL pre trip inspection checklist trip up new drivers most often:

- Chocks: During your CDL class a pre trip inspection, you'll have the vehicle on and off, and be testing various brake systems. Chocks prevent the truck from moving around while you're underneath and walking around.

- Seatbelts: It's often the last thing on a new driver's mind on the long list of items to inspect. But, your life depends on it.

- Emergency Kit: Especially if you drive a shared truck, you don't know if the previous driver used up anything in the kit. Just because you see the kit doesn't mean everything is present and functional.

- Reflectors: Reflectors help other vehicles see you at night. Because there are so many, drivers rush through this check or give them a quick glance. These are another "gateway violation" that can get you pulled over and given a roadside inspection.

- Wheel Lug Nuts: Loose wheel fasteners could have your tires speeding down the freeway toward other cars and trucks. Double-check that all lug nuts are fastened and free of rust.

- Personal Health: Remember the figures we mentioned about truck driver life expectancy. Put your health first, and don't drive if you feel sick and feverish.

This is all about the safety of you and others. Keep your pre trip inspection Class A cheat sheet with you and go through the same, thorough motions every time.

CDL Class B Pre Trip Inspection

The CDL Class B pre trip inspection follows virtually the same guidelines as Class A, but they differ in terms of vehicle type.

Class B includes buses, straight trucks, and smaller commercial vehicles that are typically not designed to tow additional trailers. Items like the 5th wheel and coupling mechanisms are obviously left off. Drivers have to check passenger doors, wheelchair lifts, handrails, emergency exits, and seating for passenger safety.

New Truck Pre-Inspection Checklist Addition

Non owner-operators who are regularly assigned new trucks can't take for granted that everything was left as you might have left it. Add these to your pre-inspection checklist:

- Cab card & book: permits, registration, IFTA paperwork, and cab cards are present and up-to-date

- IFTA Sticker: current year is displayed on both sides of the truck

- Elog Device: present and functional

- Permits: in the cab card book and up to date

- License Plate: front and back plates match

- Medical Card: med card and CDL are on your person or in the truck

- Paper Logbook: backup if E-log stops working

- Inspection sticker: stuck to the side of the truck and up-to-date

- FMCSA Safety Book: within arms reach of the driver's seat

Additional Supplies: load securing equipment, extra coolant and oil, cable cutters, hammer and wrench, hard hat, and steel-toed boots, and any wisdom you've gained from recent semi truck shows for the latest in safety and efficiency enhancements.

Final Notes on Completing Your CDL Pre-Trip Inspection Checklist

So, you're armed with the ultimate CDL pre trip inspection checklist that will help you pass your exam and save on vehicle maintenance. Your truck is your money maker; our goal for this guide is to give drivers the tools to protect their biggest asset and keep the most money in their pockets as they can. That includes showing you the best truck driver accessories and the best trucking GPS , so you'll be set for the long-haul.

Learn more about how to earn more money and truck driver pay in our blog . Here's another link to the pre trip inspection Class A PDF . Good luck!

Join Our Newsletter

Discover tips, trick, and tools to grow your business faster than ever! Plus - exclusive giveaways, discounts, and new feature releases.

The Cota Systems Blog

Discover new tools, tips, and tricks to drive the growth of your business.

What is Consolidated Freight? Shipping Secrets

#1 Ultimate Freight Broker Guide: Results You’ll Love

FREE South Carolina CDL Pre-Trip Inspection Practice Test 2024 | SC

Looking to receive your pre-trip inspection endorsement? The best place to start your journey is right here with our free South Carolina CDL Pre-Trip Inspection Practice Test. Earning your pre-trip inspection endorsement will demonstrate to potential employers that you have the inspection knowledge to help ensure your safety as well as the safety of the drivers you share the road with. Our practice test includes 30 questions similar to these: For manual slack adjusters, what must you check that doesn’t move more than one inch (with the brakes released) when pulled by hand? What should you check to see that it is secure, free of damage, and strong enough to contain cargo (if equipped)?

To pass this pre-trip inspection practice test, you need to achieve a score of 80% or more. Our test questions are drawn from the South Carolina CDL Handbook and are multiple choice in format just like on the real test. You will be given four possible answers and you will be required to select the correct one. Our practice test covers the very same subjects found on the real exam to ensure you have the best possible study aid available. In fact, many of our questions are so similar to the real thing that they could possibly show up on test day! Take the test now to get familiar with the content and format of the real test before you visit the DMV. Get started.

South Carolina CDL Pre-Trip Inspection Overview:

Get the latest (2024) official SC CDL Manual.

Select Another SC CDL Practice Test

- General Knowledge Test 1

- General Knowledge Test 2

- General Knowledge Test 3

- SC CDL Air Brakes Test 1

- SC Combination Vehicles Test 1

- SC CDL HazMat Test 1

- SC CDL Tanker Vehicles Test 1

- SC Double/Triple Trailers Test 1

- SC Passenger Vehicles Test 1

- SC CDL School Bus Test 1

- SC CDL Pre Trip Inspection Test 1 (you are here)

- General Knowledge Test Simulator

Complete pre-trip inspection checklist for truck drivers

By The Schneider Guy

Estimated reading time: 4 minutes

As a truck driver, performing a CDL pre-trip inspection is one of the most common and repeated tasks you will complete. Pre-trip inspections help truck drivers ensure their tractor and trailer are safe to operat e before hitting the road.

Keep reading to learn what a p re -trip inspection is and what should be on a p re -trip inspection checklist .

What is a pre-trip inspection?

A pre-trip inspection includes checking over the tractor and trailer a truck driver will be operating . A pre-trip should be completed before the operation of a vehicle :

- At the beginning of a driver’s shift.

- Any time a new trailer is picked up.

- After a 10-hour break.

A thorough inspection usually takes anywhere from 30 minutes to one hour and should be logged as on-duty, not driving (line 4) .

How to complete a CDL pre-trip inspection

CDL pre-trip inspection checklist

1. passenger-side engine: .

- Air filter housing: Secure mounting, cover in place.

- Windshield washer fluid reservoir: No leaks, proper fluid level.

- Turbocharger: No oil or exhaust leaks.

- Engine air ductwork: No cuts, clamps secured.

- Alternator: Mounting secured, no broken or loose wire.

- Accessory drive belt: Not cracked or frayed.

- Air conditioner compressor: Secure m ounting .

2. Front brakes (covers all five brake components):

- Brake drum: No cracks.

- Brake lining: No cracks or damage.

- Slack adjuster: Proper angle to the brake chamber, clevis and cotter pin intact.

- Brake air line: No bulges or cuts, fitting tight .

- Brake chamber: Mounting bolts secured, band clamp secured.

3. Front wheel:

- Tire: ABCs (abrasions, bulges, cuts), pressure = 120 PSI, tread depth = 4/32 min ( DOT ) .

- Wheel: Not cracked or bent.

- Hub oil: Not leaking, at proper level – if it’s a sealed unit, can’t check level.

- Oil seal (outer): Not leaking.

- Valve cap: Not missing.

- Lug nuts: None missing, no streaks or shiny areas, none loose.

4. Driver side of engine:

- Radiator brace: No cracks or missing bolts.

- Radiator: Not leaking, secure mounting.

- Water pump: No cracks, not loose or leaking.

- Fuel water separator/filter: Not leaking, secure mounting.

- Pitman arm/drag link: Not cracked, castle nut secured with cotter pin.

- Steering gear box: Secure to frame, not leaking.

- Power steering reservoir: Secure mounting , no leaks, proper level.

- Dipstick: Right level, secured after check.

- Steering shaft: Secure, not loose or damaged.

- Fuel pump: No cracks, not loose or damaged.

- Oil filler cap: Secure, no cracks.

- Engine coolant reservoir: No leaks, proper fluid level.

5. Steer axle suspension:

- U-bolts: No cracks, no loose or missing nuts.

- Leak spring: No cracks, not loose or shifting.

- Tie rod: Secured with castle nuts and cotter pins.

- Shock absorber: Secure mounting, not leaking oil.

- Axle: Not cracked.

6. Rear suspension:

- Spring mount: No cracks, secure mounting.

- Tire: ABCs (abrasions, bulges, cuts), pressure = 110 PSI, tread depth = 2/32 min ( DOT ) .

- Airbag (bellows): Fully inflated, secure mounting, not ruptured.

7. Side of cab:

- Mirrors: Secure m ounting , no broken glass.

- Doors: No damage, glass not broken, hinges secured, opens and closes well.

- Lights and turn signals: Working, not cracked.

- Steps: Mounted, secured to skirting.

- Battery box: Secure m ounting , cover latched.

- DEF cap: Cap secured.

- Fuel cap/tank: Gasket in place, vent in place, chain secures the cap to the tank.

- Side skirting: No damage, panels secure.

- Side box: Secured, safety triangles present.

- Side of sleeper berth: No body damage.

- Sleeper berth window: No cracks.

8. Rear of cab:

- Electrical cord: No bare wire, no corrosion, check the plug at the end of the cord.

- Air line: Not tangled or worn, rubber grommets not worn, fittings tight.

- Cab shock absorber: Secure mounting, not leaking oil.

- Cab airbag (bellows): Not ruptured, securely mounted.

9. Driveshaft/rear frame:

- Driveshaft: Not cracked.

- Universal joint: Not cracked, not missing bolts, no shiny areas.

- Differential: Not leaking oil.

- Frame: Straight, no non-factory welds.

10. Fifth wheel area:

- Pivot pin: Keeper pin and cotter key intact.

- Slider lock pins: Fully engaged.

- Release arm: Not bent.

- Slider rail: No broken welds or missing bolts.

- Slider stop blocks: Welds not broken, not missing bolts.

- 5th wheel platform: Well-greased, tilted down.

11. Front of trailer:

- Top rail: No cracks or collision damage.

- Clearance lights: Not broken, working properly.

- Registration: Not missing, readable.

- Document box: Not missing or loose.

- Air line /glad hands: No bulges or cuts in air lines, rubber grommets not damaged on glad hands.

- Electric hook up: No broken pins, cover intact.

- PM sticker: Current, legible.

- Height sticker: Legible, legal for route.

- Placard holder: Not broken or missing rivets.

- Tracking device: No cracks or collision damage.

12. Side of trailer:

- Top rail: Not cracked, no collision damage.

- Clearance light: Not broken, operational.

- Bottom light: Not cracked, no collision damage, no missing bolts.

- Landing gear: Legs straight, no broken welds in bracing, sand pads secured and clean handle in cradle.

- Reflector tape: Clean.

- Side panels: No holes or cuts, no missing rivets.

13. Rear of trailer:

- Latches: Secured, not damaged.

- Lights: Not broken or missing, operational.

- Splash guard: Brackets and guard secured.

- License plate: Secure and clean, light is working.

- Bumper: Not damaged, no broken welds.

- Door hooks: Not loose, no missing bolts.

- Hinges: Not cracked, no missing bolts on both sides.

- Door seals: No separation, no rubber tubing sticking out.

14. Trailer suspension:

- Air line: No bulges or cuts, fittings are tight and not rubbing.

- Axle: Not bent or broken.

- Clevis pin/cotter key: Not missing.

- Slack adjuster: Proper angle, clevis pin and cotter pin intact.

- Brake linings: Minimum of ¼ inch thick, not cracked.

- Brake drum: Not cracked.

- Tire: (ABCs), tread depth = 2/32 , air pressure = 110 PSI.

- Spring: Not broken, not shifted.

- Spring mount: No broken welds.

- U bolts: Not loose, not cracked.

- Torque rod: Secure mounting, bushings intact.

- Spring brake chamber: Secure m ounting , band clamp secure.

15. Gauges/inside the truck:

- Fuel: Matches visual when looking in the tank.

- Def level: Maintain a minimum of one light bar.

- Oil pressure: 25-50 PSI.

- Speedometer: 0-60 MPH.

- Air pressure: 90-120 PSI.

Please note that the list above is just an example. It is important to remember the type of driver you are, the company you work for and the type of truck you drive can impact your CDL pre-trip inspection . Be sure to consult your company guidelines or speak with your leader for more information on your post-trip inspection requirements.

Get more great driving tips and guides.

Schneider Guy loves the "Big Orange." He's passionate about the trucking industry and connecting people to rewarding careers within it. He's been the eyes and ears of our company since our founding in 1935, and he's excited to interact with prospective and current Schneider associates through "A Slice of Orange."

Related posts

8 CDL Road Test tips to help you pass

How hard is it to get a CDL?

How to get your CDL – 7 simple steps for new truck drivers

- Connecticut

- District of Columbia

- Massachusetts

- Mississippi

- New Hampshire

- North Carolina

- North Dakota

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- West Virginia

- Help center

- Send email

- Premium Login

- Car

- CDL (Commercial Vehicles)

- Motorcycle

- Last-Minute DMV Tips

- Driving Tips

- Help Center

Your Progress

- 0 Incorrect ( 4 allowed to pass )

- 0 Correct

- Answer popularity

- Font size Default A A

- Keyboard shortcuts Shift + ?

How to Pass The First Time

- Practice with the Free tests

- Unlock 67 Premium tests

- Review our Premium Cheat Sheets

or we return 100% of your money

- Back to all tests

- View Handbook

SC CDL Pre-Trip Inspection Practice Test 2024

- Perfect for first-time and renewal CDL/CLP applicants, and those adding endorsements

- Based on 2024 SC commercial driver's license manual

- Triple-checked for accuracy

- Updated for September 2024

What you need to know

Do you think you are prepared to take the SC CDL Pre-Trip Inspection Exam? If you are not sure if you’ll pass, it is a really bad idea to go to the DMV and take the exam. You could fail it, and that will make it difficult for you to maintain your job. It is much better to prepare ahead of time by taking our CDL Pre-Trip Inspection Practice Test. It will make it much easier for you to go into the SC DMV and pass with flying colors.

Learn from Your Wrong Answers

You might not get each answer correct the first time, and that is fine. You can learn from the answers that you miss. When you miss a question, the test will let you know. It will highlight the correct option so you can make a note of it. This will let you know what you need to study up on. For instance, you might not know anything about checking the oil level, so you might miss a question about that subject. That will let you know that you need to go back through your SC manual and review that section before you go to the DMV.

Prepare for Exam Day

When you finally get all of the practice test questions correct, you’ll know that you are ready for test day. At that point, don’t put it off. There is no sense in putting it off any longer. You’re now ready to go to the DMV. You should have a lot of confidence now since you have practiced here. The tests are very similar, so there is no reason to think that you won’t do the same thing on the official exam.

So, now it’s time to buckle down and get ready for big day. Begin with the practice test, paying attention to each question that you face. After you make it through the practice test, you’ll finally be ready to go to the DMV and take the real thing.

Thoroughly prepare for your CDL Pre-Trip Inspection with our detailed guide, offering step-by-step procedures and essential tips at our Pre-Trip Inspection section .

What to expect on the actual exam

correct answers to pass

passing score

Helpful links

SC DMV website

Official South Carolina CDL manual (2024)

More resources

- SC CDL Pre-Trip Inspection Test

- SC CDL Pre-Trip Inspection Exam Simulator

- Alabama: Test 1 / Test 2

- Alaska: Test 1 / Test 2

- Arizona: Test 1 / Test 2

- Arkansas: Test 1 / Test 2

- California: Test 1 / Test 2

- Colorado: Test 1 / Test 2

- Connecticut: Test 1 / Test 2

- Delaware: Test 1 / Test 2

- District of Columbia: Test 1 / Test 2

- Florida: Test 1 / Test 2

- Georgia: Test 1 / Test 2

- Hawaii: Test 1 / Test 2

- Idaho: Test 1 / Test 2

- Illinois: Test 1 / Test 2

- Indiana: Test 1 / Test 2

- Iowa: Test 1 / Test 2

- Kansas: Test 1 / Test 2

- Kentucky: Test 1 / Test 2

- Louisiana: Test 1 / Test 2

- Maine: Test 1 / Test 2

- Maryland: Test 1 / Test 2

- Massachusetts: Test 1 / Test 2

- Michigan: Test 1 / Test 2

- Minnesota: Test 1 / Test 2

- Mississippi: Test 1 / Test 2

- Missouri: Test 1 / Test 2

- Montana: Test 1 / Test 2

- Nebraska: Test 1 / Test 2

- Nevada: Test 1 / Test 2

- New Hampshire: Test 1 / Test 2

- New Jersey: Test 1 / Test 2

- New Mexico: Test 1 / Test 2

- New York: Test 1 / Test 2

- North Carolina: Test 1 / Test 2

- North Dakota: Test 1 / Test 2

- Ohio: Test 1 / Test 2

- Oklahoma: Test 1 / Test 2

- Oregon: Test 1 / Test 2

- Pennsylvania: Test 1 / Test 2

- Rhode Island: Test 1 / Test 2

- South Carolina: Test 1 / Test 2

- South Dakota: Test 1 / Test 2

- Tennessee: Test 1 / Test 2

- Texas: Test 1 / Test 2

- Utah: Test 1 / Test 2

- Vermont: Test 1 / Test 2

- Virginia: Test 1 / Test 2

- Washington: Test 1 / Test 2

- West Virginia: Test 1 / Test 2

- Wisconsin: Test 1 / Test 2

- Wyoming: Test 1 / Test 2

Your go-to, trusted source

Our commitment to accuracy and quality in our practice tests.

Explore our rigorous, multi-tiered verification process that ensures each question mirrors the official manual for unparalleled accuracy.

At Driving-Tests.org, we understand the importance of reliable and accurate practice tests to help you prepare for your DMV exam. That's why we've developed a meticulous process to create and continually update our practice questions, ensuring they reflect the most current driving laws and regulations.

Here's an inside look at how we maintain the highest quality in our practice tests.

Content Creation and Verification Process

- Alignment with Official Manuals: Every question we develop is based on the most recent version of each state's official driving manual. Our team regularly monitors each state DMV's website for the latest updates to ensure our practice tests are always aligned with the most current information.

- Community Feedback Integration: We leverage feedback from our vast community of users to understand which topics are most frequently tested. This helps us focus on the areas that are most relevant and beneficial for your preparation.

- Expert Content Creation: Our in-house editor, Steven , who has extensive experience in driver education, crafts each question with precision. He conducts a thorough review of each question against the official manuals to ensure accuracy.

- Rigorous Review Process: Once Steven has finalized a set of questions, our team conducts a joint review session. This second level of scrutiny involves content accuracy, proofreading, and fact-checking to eliminate any errors.

- User Feedback Mechanism: After a question goes live on our site, we keep the lines of communication open. Each question features a feedback button, inviting users to report any issues or errors. This continuous feedback loop allows us to address and rectify any concerns promptly.

- Responsive Updates: In line with our commitment to accuracy, we quickly update our practice questions to reflect any changes in the DMV manuals. Additionally, we update the free electronic copy of the state's driver's license manuals on our site, typically within a few days after the DMV publishes them.

Our thorough quality control process ensures that you have access to practice tests that are as accurate and up-to-date as possible. We believe in the power of well-prepared drivers and are dedicated to providing you with the best study tools to help you succeed on your DMV exam.

Keyboard shortcuts

Clear your challenge bank.

This will clear your Challenge Bank and delete all questions. This cannot be undone.

Try Driving-Tests Premium

Pass the knowledge test the first time, guaranteed.

Pass Guarantee

How does it work.

Our Premium Membership comes with a Pass Guarantee (30-day access and longer). If you successfully complete all the practice tests for your province/territory, we promise you a passing grade on your official written knowledge test or we'll refund your money. Your most recent completion of all the tests should be not earlier than 30 days before your exam date.

Just send us an email with your full name (must match the name and email address used for your purchase at Tests.ca) within 30 days from the purchase of your Premium membership.

What happens next

We'll check your account to make sure you've successfully completed all practice tests for your state. Once that is confirmed, we'll issue a full refund (you'll receive a separate email confirmation).

CDL VEHICLE INSPECTION TEST SOUTH CAROLINA

Sc cdl inspection test.

- All Companies

- Driver Training

- All Freight Types

- Lease/Purchase

- Message Board

- Truck Driver Salary

- How to Become A Truck Driver

- Will I Be Successful?

- Truck Driving Schools

- CDL Practice Tests

- Get Your CDL

- Get Your First Truck Driving Job

- Your First 100,000 Miles

- Advanced Tips

- Sign Up Here

Select Location x

Please tell us your location.

Location not set

The Complete Pre-Trip Inspection Checklist

Due to heavy memorization, the pre-trip inspection is one of the hardest aspects of the CDL test. Also called the “Vehicle Inspection Test,” the pre-trip is one of the tests that trucking students fail the most.

With this pre-trip inspection checklist, we tell you everything you need to know and what you need to check for.

Engine Compartment – What to Check For:

When checking the engine compartment, you always want to make sure the following components are properly mounted and secured. You should also make sure they are not cracked, bent, or broken. The items you need to check for include:

Belt-Driven Alternator

All of the wires are connected. The belt is not cracked or frayed, and the free play on the belt is between ½ to ¾ of an inch.

Belt-Driven Water Pump

The free play on the belt is between ½ to ¾ of an inch, and all the hoses running to and from the water pump are tightly clamped. Ensure nothing is leaking.

Brake Chamber

The brake chamber is not leaking air.

The brake drum is properly mounted and secure.

The brake hose is rubber; it is not cracked and is not leaking air.

Brake Lining

Check for oil or debris on the lining. There should be at least ¼ of an inch of friction material.

Caste Nuts and Cotter Pins

All three caste nuts and cotter pins are present.

Coolant Reservoir

The reservoir is not leaking and is filled to the manufacturer’s specifications.

The drag link is properly mounted and secure, and not cracked, bent or broken.

Gear Box and Hoses

The gear box and hoses have no abrasions, bulges or cuts, and are not leaking.

Gear-Driven Air Compressor

The air compressor is properly mounted and does not leak.

Gear-Driven Power Steering Pump

The steering pump is properly mounted and not leaking.

General Hoses (Passenger and Driver’s Side)

The hoses are secure at both ends and are not leaking. There are no abrasions, bulges, or cuts.

The hub seal (or axle seal) is leaking and is filled to the manufacturer’s specifications.

Leaf Springs

None of the leaf springs have shifted or are bent or broken.

There are no signs of leaks under the truck.

There are no lug nuts missing. There are no rust trails, powder residue, or cracks around the bolt holes.

The oil level is filled to the manufacturer’s specifications.

The pitman arm is properly mounted and secure. It is not cracked, bent, or broken.

Power Steering Fluid Reservoir

The power steering reservoir is not leaking and is filled to the manufacturer’s specifications.

The rim does not have any unauthorized welds.

Shock Absorber

The shock absorber is not leaking. If it is leaking, the leak will be at the point where the top and bottom portion of the shock meet.

Slack Adjuster and Push Rod

With the brakes released and pulled by hand, the push rod does not move more than one inch.

Spring Hanger

The spring hanger is properly mounted and secure.

Steering Column

The steering column is properly mounted and secure. It is not cracked, bent, or broken.

There are no abrasions, bulges, or cuts on the tread or sidewalls. Tread depth should have a depth no less than 4/32 of an inch. Tires are properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

The tie rod is properly mounted and secure, not cracked, bent, or broken.

Make sure all are accounted for.

Driver Door Fuel Area-What to Check For:

Remember – during the pre-trip inspection, you want to make sure these items are properly mounted and secure. Look for cracks, bends, and breaks.

The actual airbag has no abrasions, bulges, cuts, or leaks. The airbag is not missing mounting bolts.

The axle seal is not leaking and is filled to the manufacturer’s specifications.

The brake drum is secured properly and has no cracks, bends or breaks.

Check the brake hose at both ends to make sure it is not leaking air.

There is no oil or debris on the brake lining. There is at least ¼ of an inch of friction material.

Catwalk and Steps

The cat walk and steps are clear of any loose objects.

Door and Hinges

The doors open, close, and latch properly. Door seals should not be worn, torn, or rotten.

Drive Shaft

The drive shaft is not twisted, and the u-joints are free of any debris.

The tread and sidewalls have no abrasions, bulges, or cuts. The tread depth is no less than 2/32 of an inch. Tires are properly filled to the manufacturer’s specifications. This can be checked with an air gauge.

Exhaust System

The exhaust system shows no signs of leaks.

Frame and Cross Members

There are no unauthorized holes or welds. Bundle up the cross members to ensure none are missing.

Fuel is not leaking from the tank, and the cap is on tight.

There are no rust trails, loose bolts, powder residue, or cracks around the bolts.

Mirrors are clean, with no cracks or chips.

The mud flap is secured properly, with no cracks, bends and breaks.

There are no unauthorized welds.

The shock absorber is secure at both ends and not leaking. If it does leak, it is preferable to leak in the middle.

There is proper spacing between the tires and there is nothing stuck.

The spring arm is secure at both ends.

Spring Mount

The spring mount is secure at both ends.

The torque arm is secured properly, with no cracks, bends or breaks.

No u-bolts are missing.

Coupling Area-What to Check For:

Air lines should be secure at both ends with no abrasions, bulges, or cuts. They should not be leaking, dragging, or tangled.

Make sure the apron is properly mounted and secure. Look for cracks, bends, and breaks.

Make sure there is enough space between the tractor mud flap and the trailer landing gear, so that they don’t hit each other when making a turn.

Electric Line

The electric lines are secure at both ends. There are no abrasions, bulges, cuts, or exposed wires.

There is no space between the apron and the skid plate.

The seals are in good condition with no cracks, signs of rotting, or leaking air.

The king pin is properly mounted and secure, without cracks, bends and breaks.