- January 27, 2024 | Breitling Watches For Pilots

- December 22, 2023 | Mosquito Air Kit Helicopter Assembly Manual

- December 22, 2023 | Mosquito Air Kit Helicopter Operators Manual

- August 13, 2020 | Rotorway Exec Kit Helicopter 1987

- August 13, 2020 | Chadwick Helicopters C-122

Safari 600: A well-proven helicopter to build yourself

Posted By: redback February 27, 2019

COURTESY: KiwiFlyer Magazine

Magazine of the New Zealand Aviation Community

SOURCE: Issue 50 – 2017 #1

SUBSCRIBE: http://www.kiwiflyer.co.nz/

CREDITS: Michael Norton – Editor | Publisher KiwiFlyer Magazine

Flight Review

There’s a new, NZ, version of the Safari helicopter about town. And it’s much nicer to fly. About three years ago, KiwiFlyer sampled the previous edition of Bruce Belfield’s home-built Safari helicopter for a feature article in Issue 33.

For a variety of reasons, supported by second and third opinions, we concluded it was probably the pick of the rotary home-builts available in the recreational aviation market. If there was a niggle at that time, it was our perception of a heavy control feel – which we likened to an R44 with the hydraulics off.

You adjusted to it after a while, but the initial flight for pilots current in certified light helicopters would probably involve a degree of over-controlling in response to the friction and feedback present within the Safari’s systems of then. And now? Very much better.

That’s not just KiwiFlyer’s view after a brief sortie around Bruce’s patch at Te Awamutu either. Other CPLs who have tried the new version concur.

There are 12 CHR Safari helicopters on the New Zealand register. Produced as a kit-set by Florida company CHR International, the Safari has the outward appearance of a scaled down Bell 47. Indeed when first developed by Canadian Home Rotors, the aircraft was named the Baby Belle.

It was later changed to Safari and subsequently in 2009 CHR International acquired the business and moved it to Florida. Testament to the design of the Safari is the number of hours commonly flown on them. Several of the New Zealand examples have many hundreds of hours on their HOBBS.

All too often home-built helicopters change hands with very few hours on the clock, in main due to their owner/builders discovering that flying them wasn’t quite the good experience they were expecting.

LEFT: Brand new Safari 400 being test flown by Bruce. RIGHT: Main rotor blades are composite, made in the US.

That’s not the case with the Safari helicopter, whose owners frequently talk of adventures into mountains and bush on hunting, fishing and holiday trips. One of the confidence inspiring aspects of the Safari is its rugged and traditional design.

The helicopter air frame is of welded steel, the engine is a Lycoming, and everything is on show for inspection. There’s also plenty of room for two people in the cabin, a decent useful load and good power reserves.

Bruce Belfield became a distributor for the helicopter company after acquiring his kit in 1998, forming South Pacific Home Rotors in 2002. A fitter/turner and machinist by trade, his skills were a perfect match for the amateur-built aircraft category the Safari fits in to.

Those skills have also been put to good use for subsequent owner/builders with numerous improvements to the design originating from Bruce’s workshop and now distributed to owners around the world as well as the United States factory.

Safari 600 Specifications and Performance

Powered by a Lycoming O-360, the standard factory Safari 400 will cruise at 74kts, with a VNE of 87kts or 100mph. A typical ship weighs around 1000lbs empty and with a MAUW of 1650lbs, useful load is in the order of 650lbs. Climb performance is 1000 feet per minute to a ceiling of 10,000 feet.

The twin fuel tanks hold a total of 106 liters. IGE hover limits are quoted as 7000 feet and OGE as 5000 feet. The 26ft diameter main rotor is of composite construction and the tail rotor with a 4 foot diameter is made from strong and light weight titanium.

South Pacific Home Rotors

Bruce Belfield’s original Safari 400 was the first-of-type to fly in New Zealand, back in the year 2000 when it also deservedly gathered up several home-building awards from the local sport aviation scene.

Over the years since, Bruce has worked extensively to support other builders in New Zealand as well as to make numerous improvements to the helicopter’s design and flight characteristics, several of which have been incorporated by the factory into their standard kit – one example being titanium tail rotor blades.

LEFT: Everywhere you look, craftsmanship is outstanding. RIGHT: Proud new owner Colin Wade, with Bruce.

Another improvement first fitted to the helicopter by Bruce and then adopted by the factory has been an electronic governor system. Yet another is his Kiwi-Pod luggage system.

Now his latest personal Safari incorporates so many ‘Bruce version’ improvements that it has become a step change from the standard factory offering. Bruce has thus unofficially ‘named’ it the Safari 600. More on that later.

Throughout the course of his work on the Safari, Bruce has acquired an international reputation as the go-to person for ‘setting up’ the helicopter. In that regard he’s recently returned from a few weeks in Costa Rica working for an owner there, and he often travels to Australia to support owners in Sydney.

Several of Bruce’s ‘enhancements’ are in regular demand by other new and existing owners throughout the world, his exhaust and inlet manifold systems being a common example.Bruce has also regularly attended Oshkosh and Sun & Fun as a guest of the factory to meet prospective customers and act as a factory demonstration pilot for them.

Safari 600 Helicopter Kit Options

The Safari helicopter kit fits into the amateur-built category, so if you do take the option to build it yourself from a basic kit, the 51% rule means that you can also maintain it yourself afterwards.

The most popular option in Australasia is the ‘Down Under’ Starter Kit, comprising a majority of the basic components, but leaving it to the owner to sort their own engine, cabin fit-out and instruments.

In the kit are: Fabricated cabin frame and tail boom, tail rotor driveshaft, fuel tanks, basic control package, engine/rotor tachometer, rotor head and blades, main transmission, a conversion kit to mount the aircraft certified engine vertically, and tail rotor assembly and blades.

The next option up is the Safari 400 kit which includes the O-360 engine, shroud and exhaust, welded fuselage with sheet metal installed, powder coated frame and mounted bubble, leather seats and carpet, instruments and pod, governor, trim and frictions, and all the necessary small parts and raw materials to complete your aircraft.

A ready-to fly option is also available which Bruce can build for you at his Te Awamutu base, where he has support available from Central Aero Engineering at Hamilton for any engineering supervision required.

Bruce says that most of his New Zealand customers typically acquire a starter kit including frame and bubble. Then they source the engine and instruments from a timed-out R22 (or a wrecked one). Although the fabrication required to complete a kit is all uncomplicated, there is a lot of it to do.

No welding is required in the Down Under kit . Bruce also says that all parts supplied are very accurately produced and fit together as they should, thanks to extensive investment in jigging and CNC production at the factory.

He says that an honest assessment of the time required to complete a Down Under kit is 1000 hours, this including the ‘thinking’ time and being easily achievable by a builder with basic skills.Any parts can be requested ready-made from the factory or via Bruce and he says there is a long list of options to make the job easier if desired.

New Zealand customers of course have a major advantage to hand in that Bruce is here with a demonstration aircraft, a wealth of hands-on experience for building, setting up, and flying the type, and the capability to assist the build process from start to finish.

The Safari 600

Bruce’s latest edition of the Safari helicopter build is not an official factory version, but if customers wish then he can fabricate the same modifications for their aircraft.

In addition to the list of ‘Bruce’ improvements that have become standard (or nearly so) Safari fitment, the ‘600’ has an extensively reworked control system. Working closely with Paul Waterhouse at Central Aero Engineering, Bruce has made numerous small changes that together accrue towards making flying the aircraft an altogether better experience.

Paul currently maintains five Safaris on behalf of their owners and says, “it wasn’t a secret that the control characteristics haven’t been perfect. The cyclic and collective forces were quite heavy and prone to leading new Safari pilots towards over-controlling.”

Paul and Bruce did “a lot of analysis and staring at other two-bladed rotor heads,” an exercise that culminated in changes to pitch link arm alignment and various other components – particularly also with a view to managing friction in the control system. In Paul’s words, “it’s pretty close to right now” .

Paul also says, “I’ve got no hesitation at all to fly in one.” Paul’s latter statement is qualified by him adding that there are very few home-built helicopters that achieve an acceptable standard for him to fly in.

Other design changes include canting the main rotor transmission forward slightly, an all-titanium tailboom – for strength and weight savings, new pedal linkages which are more positive in action, a widening of the internal frame leading to more cabin room, angling the cabin floor to be flat at cruise speed, a transmission oil cooler which now provides for an indefinite hover time, and a new collective actuator system which operates in descent at <18” MAP to help prevent the collective wanting to rise (a previous Safari niggle).

Compared to the standard model, the Safari 600 is 50 lb lighter. Bruce says that one-up, it climbs easily at 1200 fpm.

Flight Experience

As well as a brief fly of the Safari 600 ourselves, KiwiFlyer also spoke with local commercial pilot Nick Lane (4 years and approaching 1000 hours on his CPL), who is familiar with both the Safari 400 and new 600 versions.

A pre-flight is straight forward, with virtually everything you might want to inspect being clearly on show right in front of you. Climbing aboard is equally straight forward so long as you remember to put your head in the bubble and follow with your body – it simply won’t work the other way around unless you’re less than four feet tall.

Seats are very comfortable, there’s a heap of elbow room, and leg room is equally generous. I’m a touch over 6 foot and have always found the pedal position in Robinson R22s or Hughes H300s right on my comfort limit – and occasionally beyond it, resulting in cramping muscles which aren’t conducive to hovering a helicopter in a gusty crosswind. Not so in the Safari.

Bruce’s floor and pedal modifications suited me very well.Checks are all standard practice and the venerable Lycoming roars into life. As an aside I did also observe Bruce flying from the ground – and this is a noticeably quiet helicopter.

The noise footprint is unlikely to ever bother neighbors.Bruce flew a circuit to reacquaint me, then it was my turn. Three years ago, that was a bit of a humbling experience and I’ll admit it took me the best part of an hour to get to grips with the aircraft.

The difference this time was significant. In the same way that others who have flown the ‘600’ have found, a few minutes was enough. That’s mainly because the controls are much lighter and better balanced now. It’s a lot more like flying an R22 than previously.

Vibration levels and stick shake all seemed low too, suggesting a well ‘sorted’ machine. We depart for a local scenic and I also notice how much nicer the aircraft feels to just ‘fly around in’ .

Bruce says that’s due to the helicopter mast adjustments and also in part to his tilted floor. Flying ‘on the numbers’ is easy and in the light breeze we’re flying in, Bruce can readily trim the helicopter for hands-off flight if he wishes.

Confirming my perceptions in a later discussion, Nick Lane observed that it ‘wants’ to fly at 60 kts now instead of 40 kts previously whereupon it always felt like you were forcing it to go faster.

Nick says in his view the controls are “much improved” and although, like many aircraft it has its idiosyncrasies, “once you’ve got a feel for it, it flies nicely.” He says to Bruce, via our discussion, “The way it is now is good. Leave it alone.”

In Nick’s view, and mine, someone with R22 experience and Robinson Safety Course currency, would transition to the Safari 600 quite well. Being in the experimental category, pilots require a PPL(H) to fly the Safari.

Most owners either have a license or acquire one in an R22 whilst building their aircraft. However Bruce says that pending a willing Flight Examiner (currently in the pipeline), it will be possible to undertake all one’s training in the Safari if desired.

For more information on this kit helicopter

One final testament to these aircraft, worthy of mention, is that full-cover insurance is now available with a reasonable excess and premium equal to or better than what most R22 helicopter owners would receive.

To find out more, contact Bruce Belfield at South Pacific Home Rotors on 027 696 5159 or 07 871 5699, by email: [email protected] or visit www.safarinz.com

The factory website is www.safarihelicopter.com

New owner profile: Colin Wade

Our visit to Te Awamutu coincided with an opportunity to meet new Safari owner Colin Wade, who was enjoying some time in his brand new helicopter with Bruce. A Cirrus SR20 owner/pilot, Colin is yet to commence his PPL(H) and plans to use the Safari for his training. We asked Colin about the motivation behind his new acquisition.

It was quickly obvious he is a passionate aviator, first flying with Max Clear and Bantams at Te Kowhai, before stepping up to a Sky Arrow, then Pioneer 300 and then a PPL in his Cirrus which he regularly flies between Te Kowhai, Pauanui and Great Barrier.

Colin has long been an aviation enthusiast and this year will attend Oshkosh for the 15th time, traveling (as always) on a Gaye Pardy tour which he and wife Sue have often helped run for Gaye.

It was at Oshkosh that Colin first met Bruce (when he was demonstrating the factory machine there). Colin says he went for a couple of flights and was hooked, telling Bruce to call him when he got home.

Bruce later landed his Safari at Colin’s front door and the deal was done, with Colin observing that Bruce’s workmanship was exceptionally good and confidence inspiring (KiwiFlyer agrees). Colin’s aircraft has been built up by Bruce and Colin over the last 18 months and has just had the mandatory 40 hours of test flying finished off by Bruce.

Colin says the Safari suited him very well with its manageable maintenance costs, decent useful load and power in reserve, and that he’s looking forward to a lot of local flying and being able to drop in on rural friends.

Congratulations on the aircraft Colin. It looks outstanding.

LEFT: All Safaris are fitted with NZ made titanium blades. MIDDLE: Bruce is experimenting with the adjustable airfoil. RIGHT: Very nicely designed and fabricated panel.

Related Articles

Helicopter Reviews

Canadian Home Rotors Safari Kit Helicopter

Canadian Home Rotors

The Early Days Of Canadian Home Rotors

Helicopter Historical Articles

A Helicopter In Every Garage

Robinson Piston Helicopter Manufacturer

Be the first to comment on "safari 600: a well-proven helicopter to build yourself", leave a comment cancel reply.

Your email address will not be published.

Safari Helicopter

Safari Helicopters

Safari Helicopter specializes in American-made, fully-customizable personal helicopters:

There was once a time when only the most accomplished people afford motor vehicles. Today, it seems like everyone has at least one car parked in the garage. Most families have two or more. Helicopters, however, are still outside the financial reach of the common man. Those who have built their empires, however, can enjoy the thrill of flight with their very own personal helicopters from Safari Helicopter.

The Canadian Home Rotors Safari Helicopter Company

The Safari Helicopter adventure started in the early 1960s when an aerospace engineer and his son designed a personal helicopter that experienced builders could put together at home. Over the decades, these helicopter plans passed from owner to owner. Canadian Home Rotors, Inc. used this as inspiration to reach even higher by designing a helicopter that offered the safety and convenience of modern technology.

Canadian Home Rotors started tinkering with its design in 1962. It didn’t make the chopper available until 1992, when it unveiled the Safari at a national convention in Oshkosh, Wisconsin. The company didn’t even need to advertise its products. Word of mouth was more than enough to flood it with orders.

Since then Canadian Home Rotors has tested and revised every piece of the Safari helicopter. Today, it has one of the world’s most successful personal helicopter designs. Successful men interested in exploring the world need this type of vehicle to push themselves beyond ordinary limits.

Making the Most of Every Adventure

The current version of the Safari helicopter includes several high-tech features that make it extremely safe and useful for experienced pilots. The helicopter comes with a 180 horsepower engine capable of carrying 650 pounds in addition to the craft’s weight. The 4130 Chromoly steel aircraft tubing frame, titanium shafts, and aluminum sheet metal cabin keep the weight as low as possible while protecting Safari’s essential parts from harsh weather.

Safari’s cabin offers a 70-degree view of your surroundings. This makes it perfect for exploring uncharted terrain. No matter where you go, you always have a clear, unobstructed view of your surroundings. This helps keep you and your passengers safe while thrilling you with the world’s natural beauty.

The cabin also keeps you comfortable. Safari can fly in temperatures as low as -35 degrees Fahrenheit and as high as 100 degrees Fahrenheit. While high temperatures won’t prevent you from enjoying your next adventure, sub-zero temperatures could prove hazardous. Safari has a cabin heater that keeps the helicopter’s interior comfortably warm even in freezing environments.

Buying a Safari Helicopter

Safari gives you several purchasing options. Depending on how much money you want to spend and how much experience you have building vehicles, you may want to choose a:

- Safari Starter Kit

- Safari 400 Kit in Stages

- Safari 400 Complete Kit

- Safari 400 Flight Ready

Experienced builders who don’t need to worry about the money will likely prefer the Safari 400 Complete Kit. This includes every piece needed to build a functional Safari helicopter. If you don’t have the time or experience to build the helicopter on your own, you can choose the Flight Ready model. It costs a bit more, but it’s ready to fly on the day it arrives. The Flight Ready model has even gone through 20 hours of testing.

Accessories for Your Safari Helicopter

Depending on how you want to use your Safari, you may want to buy some accessories. Popular options include:

- Safari pontoons for landing on the water

- Agricultural spray systems for tending crops

- Heliport trailer for moving your helicopter by land

The Safari offers an unparalleled experience that will make you the envy of friends. When it comes to exploring the world, you just can’t beat a personal helicopter.

Helicopter Insurance

For insurance, check out Insurance Coverage | Safari Helicopter | Small Helicopter for sale to see all insurance options.

GET 10% OFF YOUR FIRST ORDER

Can Anyone Build a Helicopter? Top 5 Kits

The dream of owning your own helicopter for most people is just that, a dream. The high price tag of a helicopter makes it out of reach for most people, but for those with a mechanical mind, basic tools, and a workshop, the many helicopter kits available can make that dream a reality.

I remember watching a TV show many decades ago about a guy who bought his own DIY helicopter kit and built it. Fascinating to watch, it showed just how well a modern DIY kit helicopter can be assembled by the average Joe.

Helicopters to design and build from scratch are very difficult and require a lot of expensive research & design. A helicopter kit from an established helicopter manufacturer can allow the average person to build and fly their own helicopter for around $50,000 and 500 hours of assembly time.

If the challenge of building and owning a helicopter is something that interests you then read on to find out which are the best helicopter kits on the market today.

What is Needed to Build a Kit Helicopter?

Some engineering knowledge and experience working with basic tools are beneficial to building a kit helicopter. Most kits are assembly-only using basic tools and following instructions. A dry and clear area to build the kit will be required during the many months of assembly.

Building an aircraft can be as much of a challenge as learning to fly it but with today’s modern helicopter kits, the manufacturers have spent a lot of time and effort to create a kit that not only assembles easily but also requires very little mechanical experience.

Most of the intricate or specialist components are manufactured, assembled, and then calibrated in the factory so all the customer has to do is assemble ‘Modules’. Welding and sheet metal are usually always done at the factory as this can require specialist skills and tooling which most kit builders do not have.

The Easier the Manufacturer Can Make the Kit to Assemble, the More Kits They Sell – Simple.

Some of the main things a potential kit buyer needs to possess are being able to follow plans and read engineering diagrams, have a methodical approach to working through tasks, and a basic set of tools, most of which can be purchased at your local hardware store or online like Amazon.com

One of the most important elements to successfully building a helicopter is having a dedicated space to assemble the kit. An area that is dry, protected from wind, rain, dust, moisture, and is close by is paramount. The closer the assembly area is to your home, the easier it is to do another step in the build when you get a ‘Spare 10 minutes’.

The assembly area does not have to be huge, but as the kit begins to come together a typical garage will be the minimum size to build it. The other thing to remember is that once it is built you cannot just fly it off your neighborhood driveway to your hanger or friend’s farm. It would be a better option to remove the rotorhead and trailer it to an area at which it can be inspected and test flown.

Wire-Locking Pliers Will Become Your New Best Friend!

Some kits may vary in the depth of the build. Some will be ‘Assemble Only’, whereas some may require the manufacture of items or sheet metal. To give you some idea of the type of tools most helicopter kits will require, see below:

- Metal Shears

- Die Grinder

- Hand Grinder

- Bench Grinder

- Sanding Drum

- Belt Sander

- Drill Press

- Countersinks

- Center Punch

- Screwdrivers

- Pop Rivet Gun

- Cleco Fasteners (Amazon Link for Reference)

- Feeler Gauges

- Disc Sander

- Wet & Dry Sand Paper

- Wire-Locking Pliers (Amazon Link for Reference)

- Spring Clamps

- Vice Clamps

- Socket Sets

If you would like to see a more comprehensive list of the most common tools used to build and maintain aircraft please visit my Aircraft Tool Section in my Amazon Store HERE

Also bear in mind most kits come unpainted, so an area large enough for you to prep, paint, and dry the fuselage, tailboom, cowling covers, and components will also be required. Painting an aircraft is a very important step and should not be rushed. Also, be aware that paint will need to withstand spillages of aviation gasoline or jet fuel, depending on the engine type installed in the helicopter.

Learn More … Try These Articles: * Learning To Fly Helicopters – Is it really that hard? * Thinking of Buying a Helicopter? Best Tips From a Pilot

What are the Most Popular DIY Helicopter Kits?

Today’s DIY helicopter kit market is dominated by 5 main helicopters with varying passenger-carrying capabilities, build times, and price tags. Those helicopter kits are:

- XEL By Composite-FX

- HeliCycle By HeliCycle Ventures LLC

- Safari 400 By Safari Helicopter

- Phoenix A600 Turbo By Rotor X Aircraft Manufacturing

- Hummingbird 300L By Vertical Aviation Technologies Inc.

Let’s take a look at each of these kits individually…

Composite-FX

One of the most popular helicopter kit manufacturers in the market today provides a range of 4 different helicopter kits ranging from an Ultra-Light version to a gas turbine version. All are single-seat kits.

The XEL is the only helicopter kit that you can assemble and fly without needing a pilot license! Designed as an Ultra-Light vehicle to fall under the FAA’s Part 103 regulations, this helicopter can be flown by anyone! But, just because you do not need a license does not mean you can just jump in and take it for a ride! Training is required in a two-seat helicopter beforehand!

My students used to take on average around 10 hours just to get the art of hovering a helicopter and Composite-FX include a $5000 discount if you can show you have a helicopter pilot certificate or have gained a hovering endorsement from a Certified Helicopter Flying Instructor in a two-seat helicopter like a Robinson R22.

This Ultra-Light kit has a piston-powered engine that will give a pilot weighing no more than 240lb. a flight of up to 45 minutes cruising at speeds around 62mph. This very basic helicopter kit comes with floats as standard making it the perfect fishing machine! Just roll it out of the barn, fire it up, and off you go!

For those that wish to skip the building phase, you can buy the helicopter factory assembled for a further $11,000, and a list of upgrades allows you to customize the kit to your liking.

You can find out more about the XEL at the manufacturers’ website HERE

Join My Newsletter & Get Great Tips, Information and Experiences To Help You Become a Superb Pilot!

- Wanting To Become A Pilot

- Student Pilot

- Aready A Pilot

- Aviation Enthusiast

- Money Saving Course

HeliCycle Ventures Inc.

HeliCycle Ventures is a New Mexico-based company offering the latest evolution of the HeliCycle which has been steadily progressing since its first creation in 1997 by B.J. Schramm, the same person who also started the Rotorway International helicopter company.

The HeliCycle is now a 6th generation single-seat kit helicopter that is now powered by a modified T63-T32 100Hp gas turbine engine. It is designed primarily as a fun-fly, good-weather helicopter allowing the pilot to fly at a top speed of 110mph up to 150 miles with an aux fuel tank fitted.

Having a gas turbine allows for a much higher power-to-weight ratio allowing the pilot to weigh up to a maximum of 220lb.

This simple-to-assemble kit usually takes most builders anywhere from 400-600 hours to complete, but a fast-build option is available from the factory dropping this time to 200-300 for a further $12,000 and helps to eliminate most of the common build errors the manufacturer sees.

Once you have assembled your kit the manufacturer will send a factory check pilot to inspect, make final engine and flight control adjustments, track & balance the rotor system and complete the first few test flights to ensure your HeliCycle is safe and ready to go!

The manufacturer has left all of the avionics, radios, and electrical system out of the kit as most pilots will have different requirements as to what equipment they will need in their HeliCycle. With space at a premium, this gives the owner complete flexibility but will have to be budgeted for when purchasing a kit.

You can find out more about the HeliCycle at the manufacturers’ website HERE

Rotor X Aircraft Manufacturing

Rotor X is now the new owner of the world’s most popular helicopter kit. They purchased RotorWay in 2021 and released the latest version of their kit based on the hugely popular RotorWay Exec and A600 Talon models.

Phoenix A600 Turbo

The Phoenix A600 is a two-seat, FADEC-controlled, piston-powered helicopter aimed at looking like a true helicopter rather than a kit. The pedigree behind this latest model has allowed the manufacturer to sell over 2500 kits creating one of the best build processes of any kit helicopter.

Most of the ‘Heavy Lifting’ has been done at the factory allowing it to be an ‘Assemble Kit’ using basic hand tools and a few aviation-specific tools. No welding, sheet metal, or intense aviation engineering is required by the customer.

The A600 comes standard with dual electronic ignition, dual FADEC (Full Authority Digital Engine Control), leather seats, a digital flight instrumentation system, and a 17 gallon fuel tank giving just over 2 hours of flight. An additional ‘Aux’ tank can be added to provide a further 14 gallons extending this helicopter’s range to 278 NM.

The manufacturer has incredibly detailed assembly instructions, videos, online support, and a builders/owners online community but if that is not enough, you can also apply for their ‘Builders Assist’ program where you can pay to have someone help you build your kit.

You can find out more about the Phoenix A600 Turbo at the manufacturers’ website HERE

Safari Helicopter

Safari Helicopter produces two helicopter kits. The Safari 400 is their most popular, followed by the Safari 500.

The Safari 400 helicopter kit is positioned in the market as ‘The Complete Kit’. It can be ordered as a whole kit that gets delivered all in one go, or the customer can select to have it shipped in 4 stages to help those with limited building space.

The Safari 400 is a two-seat helicopter kit powered by a Lycoming O-360 piston engine which is one of the most reliable and popular aviation piston engines used in many types of helicopters and airplanes, not just kits. The Robinson R22 I used to instruct in has the same engine and it never missed a beat – ever!

A 28 gallon fuel tank allows this helicopter to fly for around 2.5 hours at a top speed of 100 mph.

All of the crucial construction like welding and sheet metal have been completed at the factory allowing the customer to just assemble the aircraft and paint it to their liking. The company also includes a premade wiring harness so even all the electrical equipment is just a matter of plugging it together! This makes the Safari a very attractive proposition, especially to those who are not experienced mechanics or engineers.

You can find out more about the Safari 400 & Safari 500 kits at the manufacturers’ website HERE .

Hummingbird 300L

Vertical Technologies is the only helicopter kit manufacturer to offer a 4 seat helicopter kit. Based on the Sikorsky S-52, the Hummingbird is their version to which they now own the S-52 FAA Type Certificate.

The Hummingbird 300L is based on the Sikorsky S-52 and is aimed as ‘The Family Helicopter Kit’. This 4 seat helicopter comes with two baggage areas under the 2 front seats making it perfect for stowing small luggage for a trip or weekend away, even when all the seats are occupied.

The enclosed cabin is now created using composite panels to help save weight and is all pre-fabricated at the factory so all the owner has to do is paint and install them.

The 300L is powered by a 6 cylinder, fuel-injected Continental Titan 300Hp piston engine allowing this helicopter to lift 950lb. of useful load, fly at a top speed of 105kts, and have a range of 375nm.

Just like all the other kits, the majority of the intricate assembly has been completed at the factory but allows for 51% of the assembly to be completed by the customer under the FAA’s 51% Rule (EAA.org) for kit aircraft.

This helicopter was originally certified as a commercial helicopter and as such went through stricter build protocols to meet this standard. To keep costs low for the customer they then decided to sell it as a kit but using the strict manufacturing standards to provide a higher factor of safety for their customers.

Although this helicopter requires more build time, a higher price tag, and the engine to be purchased separately from the kit, if you are looking for a cheaper 4 seat helicopter to build yourself, then the Hummingbird 300L is definitely an option.

You can find out more about the Humminbird 300L kit at the manufacturers’ website HERE .

If you wish to watch a 9-Part Series on the building of a Rotorway kit helicopter check out the video below:

A Chopper is Born

How Much Does it Cost to Build Your Own Helicopter?

A helicopter kit can cost from $50,000, then it will need shipping, paint, avionics, consumables, and an area to build the helicopter. This can push the cost up to $60,000-70,000 depending on how many extras are required. If flight training is also required then a further $5-10,000 will be required.

The cost of the helicopter kit is just one part of the cost to build your own helicopter. Careful inspection of the manufacturers’ quotation will be needed to ensure no surprises come down the road.

Here are some costs to be aware of:

Not Included in the Kit

Some helicopter kits do not come with an engine, this could be a further $60,000+ expense. Most kits do not come with a radio, some come with no electronics or instrumentation at all. Most kits come unpainted and depending on how much fuselage needs to be painted, this could cost a further $2,000-10,000.

One other consideration is crating and shipping. Many of the manufacturers offer kits to be sent in one go or in phases. Each time parts are shipped, the crating and shipping charges will be passed on to you. Be sure to check the costs of these before signing any agreement. The shipping charges alone could cost several thousand dollars!

Inspections

The FAA will require your kit to be inspected once it is complete before it is allowed to fly. This service, if completed by the FAA is free, but due to long delays, the FAA may require you to have the inspection completed by a Designated Airworthiness Representative, who may charge for their time.

The other inspection you may have to be aware of is from the kit manufacturer themselves. Some kits include a final inspection, setup, and test flight by a manufacturer’s test pilot. This may be included in the purchase price or it may be an extra cost that may be required at the end of the build.

This will be something to enquire about at the time of purchase.

For more information on FAA inspections see the FAA website HERE

Building a kit helicopter in a shed or garage is great until the helicopter begins to become too big! Finding a location that is close to home, big enough to finish the entire build, and then in a location remote enough to fly the helicopter from may require the renting of space.

Hangers at a local airport can be rented and this is where you will find most kit helicopters are built. Farms or rural properties are a second favorite as they meet all the requirements mentioned. Getting halfway through a build and then having to move can really set back the pace of the assembly, especially when all the tools and workbenches have to be moved as well as the kit itself!

Hanger or unit rental can range from several hundred dollars per month to several thousand, so looking around will be required. Also, many spaces may add in additional fees if not contracted to yearly lease terms.

Tools & Consumables

Most helicopter kits require only basic tools to assemble. There will be however certain aviation-specific tools that will be required to ensure the kist is assembled safely and to meet FAA requirements.

Cleco Fasteners Are Essential During Sheet Metal Installation

Two of the most popular tools that most people outside of aviation do not own are: (Both can be found at Amazon.com)

- Wire-Locking Pliers

- Cleco Fasters

Before the build is started it is advisable to get a ‘Tools & Consumables List’ from the manufacturer to ensure you have all the necessary tools on hand before you begin. There is nothing worse than getting a good pace and then having it stalled because you are missing a tool or a certain-sized Reamer for example.

Flight Training

No matter which helicopter kit you purchase I can tell you now that without ANY flight training, you WILL crash it on your first attempt to hover it. Hovering a helicopter is hard, really hard, and without dual controls and an instructor next to you, the machine will end up in a pile of bent parts with you wedged in the middle of it.

Even training on a PC simulator will not help you get the ‘Feel’ required to master hovering. Helicopters are susceptible to the Pendulum Effect and Overcontrolling. These two factors will need to be overcome before you can safely hover a helicopter.

Typical students will take on average around 10 hours just to begin mastering a hover, let alone safely executing an autorotation if you experience an engine failure. Helicopters are a great machine but when they bite, they bite hard and the only way to prevent them from biting or recovering from a bite is with proper training!

If you would like to find over 100 ways to save money on ANY kind of flight training please see PilotTeacher.com

Learn More … Try These Articles: * How Much Does it Cost to Become a Helicopter Pilot? * How Long Does It Take To Become A Helicopter Pilot? – Your Guide

How Long Does it Take to Build Your Own Helicopter?

On average, it takes 400-600 hours for most helicopter kits to be assembled by their owner. For a 500 hour build, working 10 hours per week will take approximately 1 year to complete. Working 40 hours per week will take around 3 months. The larger the helicopter, the more hours will be required.

Assembling a helicopter kit is not difficult but does require the methodical execution of the assembly instructions without rushing or working when tired. The assembly of the kit should be a fun part of the journey and having a dedicated space that is easily accessible will allow the build to progress at a good pace.

Any part of the build that is not fully understood should be halted until complete clarification can be sought to ensure it is assembled correctly.

Most kit builders will work on their kit in the evenings and weekends and it’s not uncommon for a build to take 1-2 years.

Do You Need a License to Fly a Kit Helicopter?

All helicopters require the pilot to hold at least a Helicopter Private Pilot Certificate to fly, except for those helicopters classed as an Ultra-Light under FAR Part 103 Regulations. These can be flown without any pilot certificate but are single-seat & will require previous helicopter training to operate safely.

The only helicopter at this time that can be flown without any pilot certificate is the Composite-FX XEL helicopter kit. This helicopter kit is purposely designed to meet the FAA’s requirements as an Ultra-Light Aircraft.

Those requirements in 14 CFR §Part 103.1 state the aircraft:

- Is used or intended to be used for manned operation in the air by a Single Person – Only one seat allowed!

- Is used or intended to be used for recreation or sport purposes only

- Does not have any U.S. or foreign airworthiness certificate

- If unpowered , weighs less than 155 pounds

- If powered , weighs less than 254 pounds empty weight, excluding floats and safety devices which are intended for deployment in a potentially catastrophic situation

- Has a fuel capacity not exceeding 5 U.S. gallons

- Is not capable of more than 55 knots calibrated airspeed at full power in level flight

- Has a power-off stall speed which does not exceed 24 knots calibrated airspeed

Once a helicopter exceeds any of those requirements the pilot is required to have at least a Private Pilot Certificate Helicopter. For those pilots who wish to own the XEL then flight training in a dual-controlled helicopter with a Certified Helicopter Flight Instructor is a must to prevent injury and damage to the aircraft.

Learn More … Try These Articles: * Buying a Helicopter? Which is the Best? * Can You Land a Helicopter Anywhere? What Will Get You Busted!

I am an aviation nut! I'm an ATP-rated helicopter pilot & former flight instructor with over 3500 hours spanning 3 countries and many different flying jobs. I love aviation and everything about it. I use these articles to pass on cool facts and information to you whether you are a pilot or just love aviation too! If you want to know more about me, just click on my picture!

Recent Posts

How Do Airports Get Their Name?

Airports get assigned their names based on a worldwide international standard. They are assigned a 4-letter code for aviation use but the airport property is often called a more passenger-friendly...

Can Airplane Windows Break?

Airplane windows can and do break. Incidents with airplane windows breaking are really common and can be dealt with relatively easily as long as the aircraft is below 10,000 feet where pressurization...

- Flight Reports

- Builder Spotlight

- Designer’s Notebook

- Customer Service

- Reset Password

- Guidelines for Writers

- Advertise with Kitplanes

- Industry News

- Kneeboard Notes

- Homebuilder’s Portal

- Completions

- Aircraft Buyer’s Guide

- Buying a Used Homebuilt

- Sign in / Join

- Free Newsletter

- Give a Gift

I spent the a few hours wandering the warbirds area this morning looking in vain for a Sea Fury, my favorite of that era, but a couple of Spitfires kept me happy. After a bit of break it was off to the kit manufacturers area in search of a plane for my girlfriend. She quite liked the Panther and Lightning so perhaps I will be roped in for some builder assistance sometime in the future.

For a couple of hours, I visited with Safari Helicopters crew, one of small number of helicopter kit manufacturers.

They have mated a composite tailboom and fuselage shell to the existing chrome moly tube-frame center section structure of their Model 400. The new Model 500 uses the existing engine, transmission and rotor system of the Model 400. Although I am a fan of the Bell-47, a legacy of watching too many MASH episodes as a kid, the new Model 500 has a much sleeker and refined appearance. The helicopter is still in development, but I was afforded the opportunity for a short flight and was able to do some basic hover maneuvers. I look forward to seeing the aircraft develop as it is one of only a few in this market segment.

RELATED ARTICLES MORE FROM AUTHOR

EAA AirVenture Cup Race Applications Now Available

Hummingbird 300L Gets Gross Weight Increase

Savoring Silver

Building the ‘Beater – Part 8

The Best Oshkosh Ever

Building the ‘Beater – Part 7

Experience for Experience Sake

Ari’s Oshkosh Video

Self-Debriefing Your AirVenture Experience

Leave a reply cancel reply.

Save my name, email, and website in this browser for the next time I comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

In Case You Missed it

What’s New

Do-It-Yourself Push-To-Talk Switch

The Art of Assembly

Ahead of its Time and Keeping Pace

- Privacy Policy

SAFARI 500 Complete Kit

Buy a safari 500 complete kit, includes everything you need nothing else to buy to buy a flight ready safari 500 call us 1-850-482-4141 or email us at [email protected].

CONTACT US TODAY TO START MAKING YOUR PERSONAL HELICOPTER DREAMS A REALITY!

Io-360 lycoming engine.

- Fabricated and Powder Coated Frame

- Carbon Fiber Exterior Cabin Shell and Assembled Tail Boom

- Cabin Completion Package

Leather Or Cloth Upholstered Seats and Fitted Floorboard Carpet

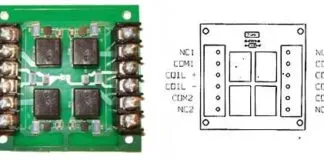

Fabricated engine cooling shroud and vertical engine conversion package, main rotor head with titanium spindle, composite main rotor blades (12’) with permanent lead/lag adjustment plates, main transmission with engine cooling fan, chip detector with alarm, sprag overrunning clutch, factory balanced tail rotor assembly with titanium blades, chip detector with alarm, engine/rotor speed governor installation package, cyclic electric trim installation package, collective friction lock installation package, curved, chrome cyclic sticks.

- Instrument Enclosure with Instrument/Electrical Installation Package

Main Rotor Tachometer with High/Low Alarm

- Gauges: Cylinder Head Temperature, Engine Oil and Transmission Oil Temperature, Engine Oil Pressure, Ammeter, Fuel Levels, Carburetor Temperature, Outside Air Temperature, Manifold Pressure Compass, Airspeed Indicator, Vertical Airspeed Indicator, Altimeter Or MGL EFIS System

- Hour Meter, Navigation, Landing, and Strobe Lights

Ground Handling Wheels and Camming Lever Assembly

Buy a safari 400 complete kit, safari 400 complete kit only $142,800only $142,800 includes everything you need – nothing else to buy.

DROOL OVER THESE!

1-850-482-4141

Fabricated and Powder Coated Frame with Internal Body Ribbing and Exterior Cabin Sheet Metal Installed

Temporarily mounted bubble and cabin completion package, composite instrument enclosure with instrument/electrical installation package, gauges: cylinder head temperature, engine oil and transmission oil temperature, engine oil pressure, ammeter, fuel levels, carburetor temperature, outside air temperature, manifold pressure or mgl efis system., compass, airspeed indicator, vertical airspeed indicator, altimeter, hour meter,navigation, landing, and strobe lights.

The Ultimate Challenge: Building A Homemade Helicopter Step-by-Step

Affiliate Disclaimer: This post may contain affiliate link or links

Homemade helicopter: Are you someone who has always had a passion for aviation and dreams of taking flight in your very own helicopter? What if we told you that you could build your own homemade helicopter from scratch?

Yes, you read that right. Building a homemade helicopter is not just a dream but a reality that can be achieved with some mechanical expertise, patience, and dedication.

While it may sound daunting, the ultimate challenge of building a homemade helicopter step-by-step can be an exhilarating journey that leads to a truly one-of-a-kind aircraft.

In this article, we will delve into the world of building your own homemade helicopter, exploring everything from legal requirements and must-needed materials to costs and the pros and cons of such an undertaking.

So buckle up and get ready for an adventure of a lifetime as we explore the world of Homemade Helicopters.

What is a homemade helicopter?

A homemade helicopter is a self-built aircraft that is made using materials and parts that are commonly found in hardware stores or online.

These helicopters can be built in a variety of styles and designs, ranging from simple models to more complex ones that require advanced mechanical skills.

Is it legal to build your own helicopter? Do you need a license?

Is it legal to build your own helicopter? Do you need a license? These are common questions among aviation enthusiasts who dream of owning their own helicopter. The answer is not a straightforward one, as it depends on several factors.

First and foremost, building your own helicopter is legal, provided you comply with the regulations set forth by the Federal Aviation Administration (FAA).

The FAA requires that you obtain an airworthiness certificate for your helicopter, which involves demonstrating that your aircraft is safe to fly.

As for licensing, the FAA requires that pilots of all aircraft, including helicopters, hold a valid pilot’s license. Therefore, if you plan to fly your helicopter, you will need to obtain a pilot’s license.

Additionally, you may need to obtain a mechanic’s license if you plan to perform maintenance on your helicopter.

It is important to note that building and flying your own helicopter is a complex and challenging endeavor that requires significant knowledge, skill, and experience.

Therefore, it is recommended that you seek the guidance of experts and professionals throughout the process.

With proper planning, preparation, and adherence to regulations, building and flying your own helicopter can be a rewarding and fulfilling experience.

Furthermore, building a helicopter is a time-consuming and expensive process. It requires a significant investment of both time and money, as well as a suitable workspace and specialized tools and equipment.

It also involves a high level of technical expertise and knowledge of aviation mechanics, electrical systems, and aerodynamics.

In addition, the FAA requires that your helicopter meets specific design and performance standards, which may require modifications or adjustments to your original design.

You will also need to obtain the necessary permits and approvals from the FAA and other regulatory agencies. Despite the challenges and requirements, building your own helicopter can be a rewarding and satisfying achievement.

It allows you to customize your aircraft to your specific needs and preferences and provides a sense of accomplishment and pride in your creation.

Building your own helicopter is legal, but it requires adherence to strict regulations and the acquisition of the necessary licenses and permits.

It is a challenging and complex process that requires significant knowledge, skill, and investment, but it can also be a fulfilling and rewarding experience for those who are up for the task.

Also see: How To Build A Helicopter At Home?

Must needed requirement to begin construction

If you’re interested in building your own helicopter, there are a few essential requirements you need to meet before you can get started. First and foremost, you’ll need to have a solid understanding of the principles of aviation and helicopter design.

It’s not enough to simply have a passion for aviation or an interest in engineering; you’ll need to have a deep knowledge of aerodynamics, structural design, and mechanical engineering.

In addition to your technical knowledge, you’ll need to have access to the necessary materials and tools. This can include everything from specialized aviation-grade metals and composite materials to welding and fabrication equipment.

You’ll also need to have a space in which to work, ideally a dedicated workshop with enough room to store your materials and work on your helicopter.

Another key requirement is funding. Building a homebuilt helicopter can be an expensive endeavor, and you’ll need to be prepared to invest a significant amount of money into the project.

This can include everything from purchasing materials and tools to hiring expert consultants to help with the design and construction process. Ultimately, building a homebuilt helicopter requires a combination of technical knowledge, resources, and financial investment.

If you’re committed to the project and willing to put in the effort, however, it can be an incredibly rewarding experience that results in a truly unique and impressive aircraft.

What is the material needed to construct one?

Building a homemade helicopter may seem like a daunting task, but with the right materials and tools, it can be done. The first and most crucial component of a helicopter is the frame, which provides the necessary support and structure for the entire aircraft.

The most common materials used for constructing helicopter frames are aluminum, titanium, and composite materials. These materials are preferred for their durability, lightweight, and high strength-to-weight ratio.

Apart from the frame, a homemade helicopter also requires an engine to power its rotor blades. The engine is the heart of the helicopter and is responsible for generating enough power to lift the aircraft off the ground.

The most commonly used engine for small helicopters is a gas turbine engine, which provides the necessary power to turn the rotor blades.

The rotor blades are another critical component of the helicopter, which provides lift and directional control. The most commonly used materials for rotor blades are composite materials, wood, or aluminum.

Composite materials are preferred for their high strength-to-weight ratio, which allows for a more efficient lift. In addition to the above-mentioned components, a homemade helicopter also requires several other components, including the tail rotor, landing gear, and control systems.

These components can be made from a variety of materials such as steel, aluminum, and composite materials, depending on the builder’s preference.

Constructing a homemade helicopter requires a wide range of materials, including aluminum, titanium, composite materials, wood, and steel. The choice of material depends on the specific application and the builder’s preference.

With the right materials and tools, building a homemade helicopter is an achievable goal for any aviation enthusiast.

Also see: Home Built Helicopters

Free homemade helicopter plan PDF download

There are many online resources that offer free plans and schematics for building homemade helicopters. These resources include forums, blogs, and websites dedicated to DIY aviation enthusiasts. While the plans may be free, you will need to purchase the necessary materials and tools to construct the helicopter.

You can download the Furia homebuilt helicopter plan by clicking the button below, it’s in PDF format, make sure you have it printed for clear understanding.

Download Furia Homebuilt Helicopter Plan PDF Free

Paid mini homemade helicopter plan PDF download

If you are looking for a more detailed and comprehensive plan, you can also purchase mini homemade helicopter plans online from Tinker Source . These plans are unique and easy to follow during construction.

These plans come with detailed schematics, instructions, and a list of materials needed to construct the helicopter. However, these plans can be expensive, and you will still need to purchase the necessary materials and tools.

How much does a homemade helicopter cost to build?

When it comes to building a homemade helicopter, the cost can vary widely depending on a number of factors. Some of the key factors that can affect the cost include the materials used, the complexity of the design, and the skill level of the builder.

Generally speaking, building a homemade helicopter can cost anywhere from a few thousand dollars to tens of thousands of dollars.

One of the biggest expenses in building a homemade helicopter is the engine. A high-quality engine can cost several thousand dollars on its own.

Additionally, the cost of other materials such as metal tubing, sheet metal, and electrical components can quickly add up.

If you have the necessary skills and expertise, building a homemade helicopter can be a rewarding and fulfilling experience. However, it is important to keep in mind that it can also be a complex and time-consuming process.

If you are considering building a homemade helicopter, it is important to do your research and carefully consider all of the costs and requirements involved.

Another key consideration when building a homemade helicopter is safety.

It is crucial to ensure that all components are properly installed and that the final product is structurally sound and able to withstand the stresses of flight.

In addition, builders should be sure to follow all applicable regulations and obtain any necessary certifications before attempting to fly their homemade helicopter.

One way to save on costs when building a homemade helicopter is to use recycled or salvaged materials wherever possible. However, it is important to ensure that all materials used are safe and appropriate for use in a helicopter.

Additionally, builders can save money by opting for a simpler design or by building a smaller helicopter that requires less expensive materials.

Overall, the cost of building a homemade helicopter can vary widely depending on a number of factors. However, with careful planning and attention to detail, it is possible to build a safe and functional helicopter at a reasonable cost.

If you are considering building a homemade helicopter, be sure to do your research and consult with experts in the field to ensure that your project is successful.

Also see: Homebuilt Helicopter Kit

Do you need a license to fly homemade helicopters?

No and Yes, you will need a special airworthiness certificate from the FAA to legally fly your homemade helicopter. Additionally, you will need a pilot’s license or be accompanied by a licensed pilot during the flight.

Further in some countries no license is required at all to fly your own homemade or home built helicopter because if anything goes wrong, you are automatically putting your own life at risk.

How much is the cheapest home built helicopter?

When it comes to flying, there are few things more thrilling than taking to the skies in a helicopter. However, the cost of owning a helicopter can be prohibitive for many.

That’s where home-built helicopters come in. These DIY flying machines can offer the excitement of flying without breaking the bank.

As for the cost of the cheapest home-built helicopter, it can vary greatly depending on the specific model and the materials used in construction. However, a quick online search reveals that prices typically start around $20,000 for a basic kit.

Of course, building your own helicopter requires a significant amount of technical knowledge and expertise, not to mention time and dedication.

But for those with a passion for aviation, the sense of accomplishment and joy that comes from flying a homemade helicopter is priceless.

What are the most popular DIY helicopter kits?

DIY helicopter kits are becoming increasingly popular among hobbyists and enthusiasts. These kits allow individuals to build and fly their own helicopters, providing a unique and thrilling experience.

Some of the most popular DIY helicopter kits on the market today include the ALIGN T-REX 500XT, the Goblin 700, the Blade 230 S V2, and the SAB Goblin Fireball.

The ALIGN T-REX 500XT is a high-performance helicopter that is ideal for advanced builders. It features a carbon fiber frame and a powerful motor, as well as advanced flight control systems.

The Goblin 700 is another popular option, known for its sleek design and impressive performance capabilities. For those just starting out, the Blade 230 S V2 is an excellent choice.

This helicopter is easy to assemble and fly, making it perfect for beginners. The SAB Goblin Fireball is another great option for those new to the hobby, featuring a lightweight and durable design.

No matter which DIY helicopter kit you choose, building and flying your own helicopter is sure to provide an exciting and rewarding experience.

In addition to the aforementioned helicopter kits, there are several other popular options available. The XK K124 is a great choice for those looking for a budget-friendly option, while the Tarot 450 Pro V2 is known for its durability and reliability.

One of the most important things to consider when choosing a DIY helicopter kit is your level of experience. If you are new to the hobby, it is important to choose a kit that is easy to assemble and fly.

On the other hand, if you have more experience, you may want to opt for a more advanced kit with more complex features.

Another factor to consider is the type of flying you plan to do. Some DIY helicopter kits are designed for 3D aerobatics, while others are better suited for aerial photography or long-distance flights.

Overall, the popularity of DIY helicopter kits continues to grow, and there are a wide variety of options available to suit any level of experience or flying style.

Whether you are a seasoned veteran or a complete beginner, building and flying your own helicopter is sure to be an exciting and rewarding experience.

Also see: Why Gyrocopter Kits Are the Future of Personal Aviation

How much does a safari helicopter kit cost?

If you’re looking to build your own safari helicopter, you’re likely wondering how much does a safari helicopter kit cost? The cost of a safari helicopter kit can vary widely depending on a number of factors, including the complexity of the kit, the materials used, and the specific components included.

On the low end, a basic safari helicopter kit can cost around $25,000, while a more advanced kit with additional features and components can cost upwards of $100,000 or more.

It’s important to keep in mind that these prices are just for the kit itself and do not include the cost of assembly, tools, or other necessary components.

When considering the cost of a safari helicopter kit, it’s also important to factor in any additional expenses such as training, maintenance, and insurance.

While building your own helicopter can be a rewarding experience, it’s important to carefully consider all of the costs involved before diving in.

Can I keep a helicopter at home?

If you’re wondering “Can I keep a helicopter at home?” , the answer is technically yes, but it’s not as simple as parking a car in your garage. Helicopters are classified as aircraft and are subject to federal and local regulations.

First, you’ll need to check with your local zoning board to see if your property is zoned for a helipad. Then, you’ll need to comply with the Federal Aviation Administration’s regulations for private helipads.

This includes obtaining a license, conducting regular maintenance, and ensuring the safety of your neighbors and the surrounding area.

Additionally, helicopters are noisy and can be disruptive to your neighbors, so it’s important to consider their concerns and any noise ordinances in your area.

Overall, while it’s possible to keep a helicopter at home, it requires careful planning and adherence to regulations.

What are the Pros of Homemade Helicopters?

One of the main advantages of building a homemade helicopter is the sense of accomplishment and satisfaction that comes from creating something from scratch.

Additionally, building a homemade helicopter can be a cost-effective way to own a helicopter compared to purchasing a pre-built one. Moreover, it can be a great way to develop new mechanical and engineering skills.

What are the Cons of Homemade Helicopters?

Building a homemade helicopter requires a significant amount of time, money, and technical expertise. Additionally, there is always a risk of mechanical failure during flight, which can be dangerous or fatal.

Moreover, obtaining a special airworthiness certificate from the FAA can be a lengthy and challenging process.

1. What materials are needed to build a homemade helicopter?

Building a homemade helicopter requires materials such as aluminum, carbon fiber, engine, rotor blades, and controls.

2. Is it legal to build and fly a homemade helicopter?

Yes, it is legal to build and fly a homemade helicopter, but it requires FAA approval.

3. How difficult is it to build a homemade helicopter?

Building a homemade helicopter is very difficult and should only be attempted by experienced professionals.

4. What safety precautions should be taken when building a homemade helicopter?

Building a homemade helicopter requires proper safety equipment, training, and compliance with regulations.

5. How much does it cost to build a homemade helicopter?

It is not possible to build a safe and functional homemade helicopter, let alone estimate the cost.

Building a homemade helicopter can be a rewarding and challenging project for aviation enthusiasts. However, it requires a significant amount of technical expertise and investment of time and money.

Before embarking on this journey, it is important to understand the legal requirements, necessary materials, and potential risks involved.

Nonetheless, with the right tools, materials, and dedication, building a homemade helicopter can be a truly unforgettable experience.

Also see: A Beginner’s Guide to Choosing the Right Gyrocopter Kit

Other related articles

Joseph Benson is content creator, writer, SEO expert and the designer of Benson-B1 ultralight helicopter and Joe Little bird Coaxial Helicopter, learn more with me.

2 responses to “The Ultimate Challenge: Building A Homemade Helicopter Step-by-Step”

I am Ronald, I want to learn how to build helicopter +256700465884

Join my new whatsapp group about home build helicopter https://chat.whatsapp.com/BYXhPSztTSM4lbQWskimL9

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

What are the Easiest Helicopters to Build at Home?

Are you a DIY enthusiast looking to explore new horizons? Have diy helicopters or the concept of build your own…

What Is The Cost of Building A Simple Helicopter Yourself?

Have you ever dreamt of soaring through the skies in your own homemade helicopter? In the world of diy helicopters,…

Do Helicopters Need Flight Plans?

In the exciting universe of aviation, one pressing question among novice pilots and aviation enthusiasts alike is: “do helicopters need…

- Search forums

- Kit Makers & Manufacturers

- Helicopters

What do you want to Know About Safari Helicopters

- Thread starter Discap

- Start date Apr 28, 2017

Junior Member

- Apr 28, 2017

I am somewhat surprised by the lack of info on Safaris the on this site. So at great personal risk I would offer all the info I have gleaned after 5 years of ownership and 250 hours of flying them. I have detailed my build on www.mykitlog.com/discap . I taught myself how to fly in it. I don't recommend this path but for some reason it is hard to find anyone that wants to give primary instruction in a homemade helicopter. I have made made substantial improvements as far as balancing goes. My lateral and vertical are below 0.1 ips in all phases of flight. Within the next two weeks I hope to start testing a device to help tame the 2/per. My ship is glass panel for several reason including data recording. I use the MGL Odyssey. So so fire away if you are interested. Bill

- Apr 29, 2017

Bill, Your build log is showing but a small specific portion of your build, is there more that I am missing? Thanks Ken

Ok that is weird. I have not been on the site in a while and I know they have made some "improvements". I found the rest of he build by tapping the blue Date in top left of any of the shown posts. After doing this go to the top and you can press ALL. That will bring up the entire build. For some reason he most recent posts are listed first the the date sorting changes from early to late so it is easier to follow. Not or sure what is going on here but I will look into it. Bill

OK, will check that out, thanks

- May 1, 2017

Not much interest here or everyone is shy. I will throw out some stuff. Performance real world. The crusing speed is more dependent on how gusty it is than anything else. I'm in Kansas and regularly fly with the windsock standing straight out. With this in mind 80 mph is doable in almost any wind conditions. I have had to slow down to 60 mph a few times for fear of unloading the rotor. If it is dead calm I have seen 100 mph. I have 4 way trim and use it 100% of the time (like on an Enstrom or MD500). A typical cross country flight 85 mph is relaxing 95 is more work and not relaxing. According to to the fuel totalizer I burn 10 gal/hr over the last 250 hours. Lots of hovering and testing. I am 240 lbs buck naked (try not to visualize that). I have flown with guys up to 260 lbs from the hover. Field elevation 1420' Density altitude 3000'. It was not pretty but it can be done. 650 lbs useful load. If I did much two up flying I would add to my counterweight because of the forward CG. Still have plenty of control but the stick is not centered. I can do pedal turns with the wind sock straight out, including back to the wind. Taxiing with my back to the wind adds 2" of manifold pressure. It does not like to do that especially with two on board. Power management is critical it seems like you never have enough unless you are by yourself and it is cold. Cold helps dramatically. Fire away, or not. Bill

Bill, honestly and sadly you will find it rather quiet here on helicopters, there are only a few here actually building any type of helicopter and no Safari's that I am aware of. I may be the only one actively (used loosely) working on one of it's predecessors, a updated/modified version of the Commuter II. There is always a lot of interest in helicopters (how could there not be haha) but unless you are building one it's only of a passing quiet interest. Do you have any measurements, internal/external, I.E. any at all on the friction clutch system? It comes complete so doubtful but no harm in asking. Any flying videos? Ken There is no flying as fun as helicopter flying, I don't care what you say :lalala:

Nope no measurements. I did assemble mine at the factory. They don't encourage working on the transmission. Pretty short on pictures. Bill

- May 2, 2017

Discap;n1119673 said: Not much interest here or everyone is shy. I will throw out some stuff. Performance real world. The crusing speed is more dependent on how gusty it is than anything else. I'm in Kansas and regularly fly with the windsock standing straight out. With this in mind 80 mph is doable in almost any wind conditions. I have had to slow down to 60 mph a few times for fear of unloading the rotor. If it is dead calm I have seen 100 mph. I have 4 way trim and use it 100% of the time (like on an Enstrom or MD500). A typical cross country flight 85 mph is relaxing 95 is more work and not relaxing. According to to the fuel totalizer I burn 10 gal/hr over the last 250 hours. Lots of hovering and testing. I am 240 lbs buck naked (try not to visualize that). I have flown with guys up to 260 lbs from the hover. Field elevation 1420' Density altitude 3000'. It was not pretty but it can be done. 650 lbs useful load. If I did much two up flying I would add to my counterweight because of the forward CG. Still have plenty of control but the stick is not centered. I can do pedal turns with the wind sock straight out, including back to the wind. Taxiing with my back to the wind adds 2" of manifold pressure. It does not like to do that especially with two on board. Power management is critical it seems like you never have enough unless you are by yourself and it is cold. Cold helps dramatically. Fire away, or not. Bill Click to expand...

Stuart, Was that main shaft calculations made on the 4130 shaft or the newer Titanium, never had heard of any issues on the older but some passing issues mention of the Titanium version. Ken

Blue Chips: My calculations were on the Titanium shaft. Very few ships use the solid shaft like Safari. It is easier to get more strength at lower wt using a hollow shaft. Safari also used a lot of 2024 T3 aluminum in non stressed areas that 6061 T6 could have handled the job at less cost and less wt. I didn't talk about it before, but I found a small spot on part of the swash plate casting. I probed it with a small needle and it fell in the hole. Careful sanding, I found a relatively large casting flaw. When I broached it with the factory, they told me to fill it up using my TIG and aluminum rod. That sure made me wonder about other aluminum castings. My bird was from a kit from 1997. It had the Ti shaft and spindles and the beefed up gear box and the @#$% spring on the collective that darn near caused a crash with me when it broke in flight. I had 235 hrs on my ship when I sold it. I had flown it at Oshkosh and at several other airshows and fly-ins. I had the 1/rev vibrations down below 0.1ips. The 2/rev was still an issue if the fuel was down around ½ tank.

Stuart, I agree with you on the hollow shaft but that would require an entirely new design so they just stick with the solid I guess. What little I know about Titanium it may not be the best choice for a main shaft. I also found the earlier Commuter II castings crude and rough, and am not a real fan of plain castings for flight critical components anyway so am machining all new swash assembly and other castings from solid 7075-T6 stock. Every one seems to complain on the 2/rev, be nice to get rid of that. One fellow here named Don apparently did but it was a rather complex and lengthy matter, believe they remedied it by making for a soft mount for the main gear box.

- May 3, 2017

Stu thanks for the comments and I will address them one at a time. Intake manifold Most people are still using the manifold you make yourself. It is indeeed a poor design, but it works. The factory now offers a cast manifold from Superior. It certainly looks better , but I have not been able to test it to determine if it actually is. The clutch does indeed chatter on engagement. The only way I see to improve this would be to tighten up the tolerances between the drive and driven parts of the clutch. The tail rotor drive bearing are the wrong ones for the application. The gears are helical cut and this cause axial thrust. The stock bearings have no thrust surface. Bearings are available that are an exact fit that do provide thrust and solve the problem. Collective spring. I have seen your Chinese weights and that certainly is a solution. The factory close a simpler one. The kit now comes with 2 spring cable assemblies instead of one. I personally prefer this solution. The seal cutting a groove in the main shaft has been addressed by installing a sleeve over the main shaft where the seal rides. I work closley with the vibration engineers at Dyna Vibe. Matt the head engineer ran calculations on the main shaft and several other areas. He found that although the solid shaft was not the "best" design that it was within what he considered the safe range. One interesting thing that came from this was that he predicted "whip" in the shaft between 80% and 87% rpm. You probably noticed it as you ran your ship up on concrete. The steel shaft did not show the whip to the same extent. The number of castings has dropped significantly. No parts in he control system are cast including the swish plate and control arms. Without the ship in front of me, the only castings that I can think of are the main transmission and tail rotor gear box. i am working on a counterweight type solution to the 2/rev problem. Just pick up,parts from my buddy with a water jet, and will star milling them this week. I have tested on a vibration bench(thanks Dyna Vibe). So now on to the real thing. Bill

Bill: Does the lead/lag adjustment of the main rotor blades still involve slightly over-reaming all of the blade retention bolt holes except one? McCutcheon told them how to get rid of the need for the Collective springs. The trailing edge heavy condition of the blades not good. Stu

- May 4, 2017

There is now a screw adjustment for the lead/lag. You can really fine tune it. I have added a chord wise balancing point so there is now also no need to use either lead/lag nor head shift in the balancing process. Set both to 0 and do the balancing on the blades and chord wise. The redundant springs have proven effective, light and simple. Kind of like Frank Robinson used to preach "add lightness".

Bill:I centered the head and had rigged up a laser pointer to get both blades straight w/respect to each other and then balanced span wise with washers added to the outer most blade retention bolt (my blade tips were the rounded variety), and then chord-wise add washers to the side of the head using the long cross bolt. Three starts I could get it down to below 0.05ips. Having had the single spring break which would have killed me had I been hand off the collective doing something with the radio, the springs didn't impress me. If it had springs holding the collective up which meant spring failure would tend to take you toward autorotation rather than away from it. The "Chinese Wts" could be adjusted to neutral collective....I've read a bunch of books on helo aero, that have said trailing edge heavy blades can take you closer to flutter. All that said, the highly modified Rotorway that I'm currently flying also has a spring on the Collective. I will be looking to get rid of it also. Well we have some helicopter dialogue going on this forum. Thanks to you. BTW the Rotorwayowners group had some discussions re: Safari going on. Two high time instructors had comments to make. Stuart

Stu you are right on the chordwise. I actually drilled additional holes on the angle brackets dedicated to the weights. The problem using the long cross bolt is that it moves the headshift depending on how tight it is. I found this out one time when I checked the headshift with a dial indicator. Turns out you cannot torque this bolt. Considering its purpose finger tight is good enough.

Platinum Member

- May 19, 2017

Discap;n1119681 said: Nope no measurements. I did assemble mine at the factory. They don't encourage working on the transmission. Pretty short on pictures. Bill Click to expand...

- May 21, 2017